Aluminum Welding Wire Products

ALLOYS AND DIAMETERS

The Nexalloy line of products are available in all standard alloys and diameters for MIG and TIG welding.

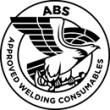

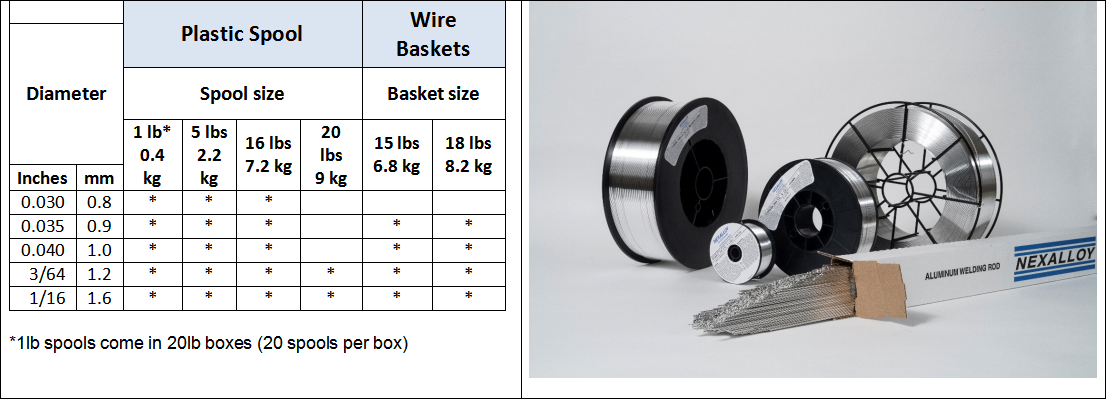

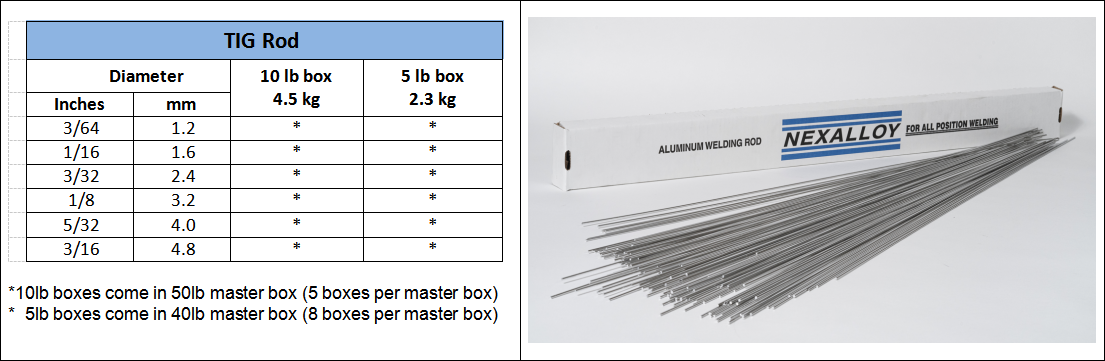

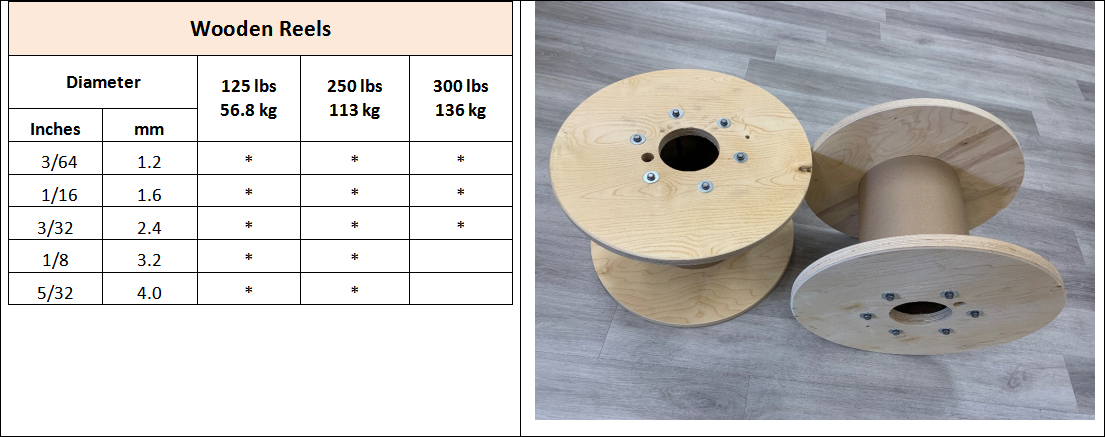

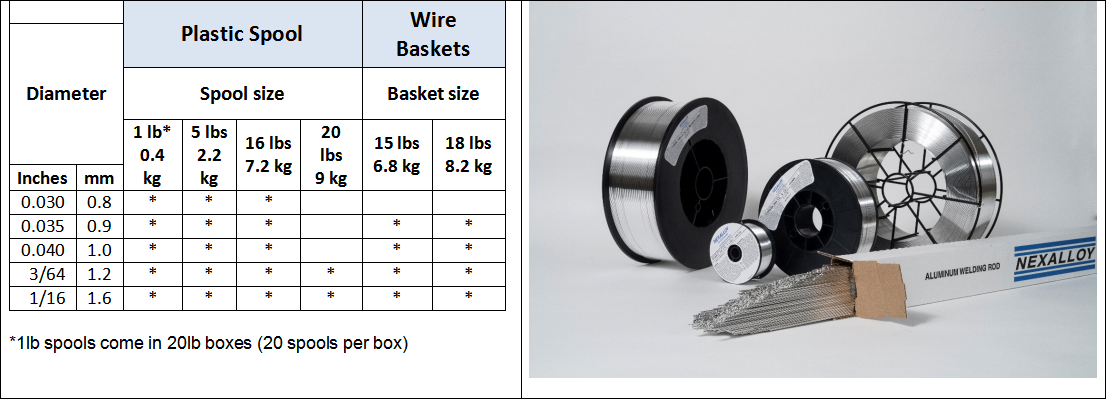

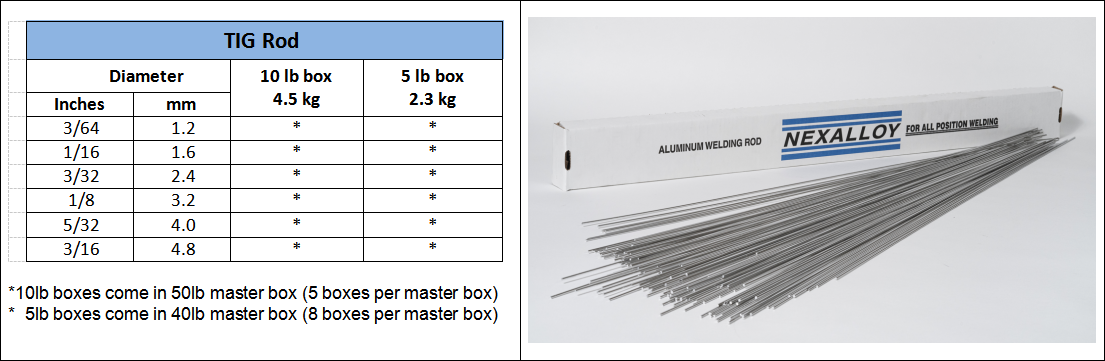

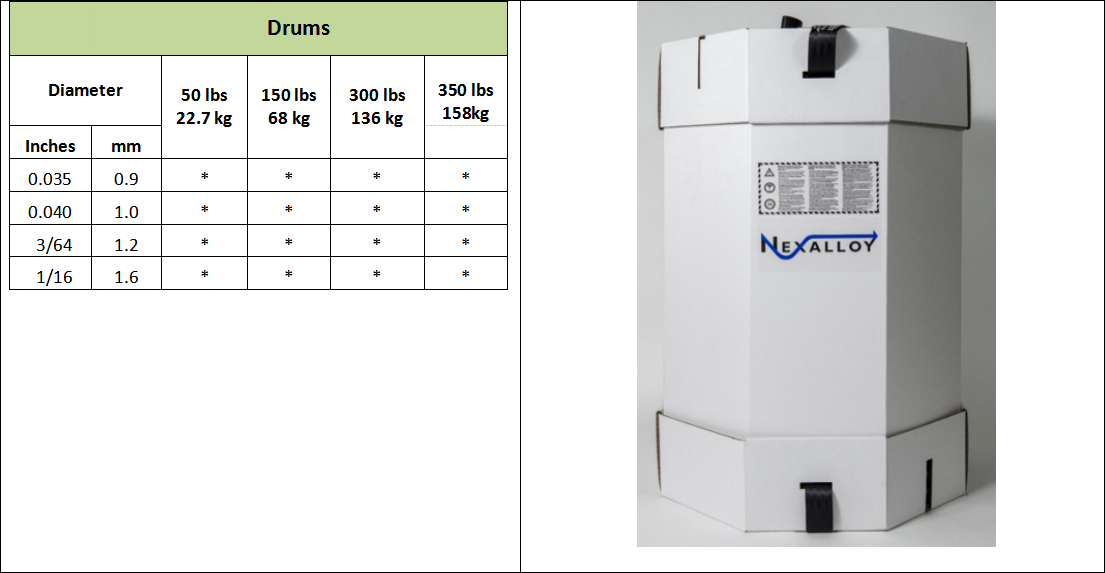

PACKAGING

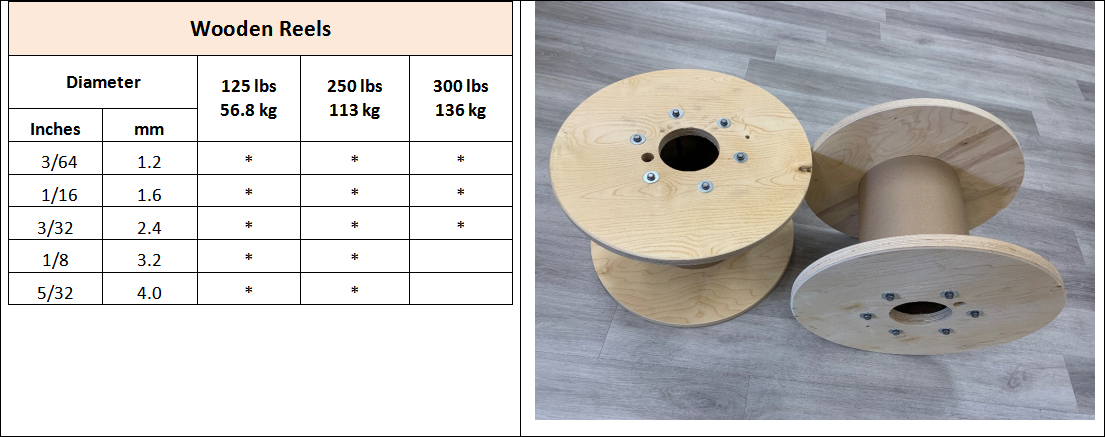

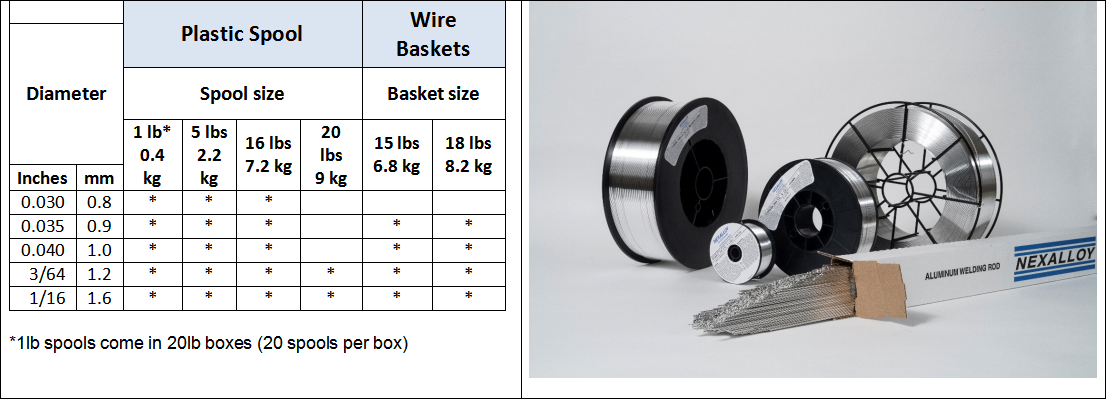

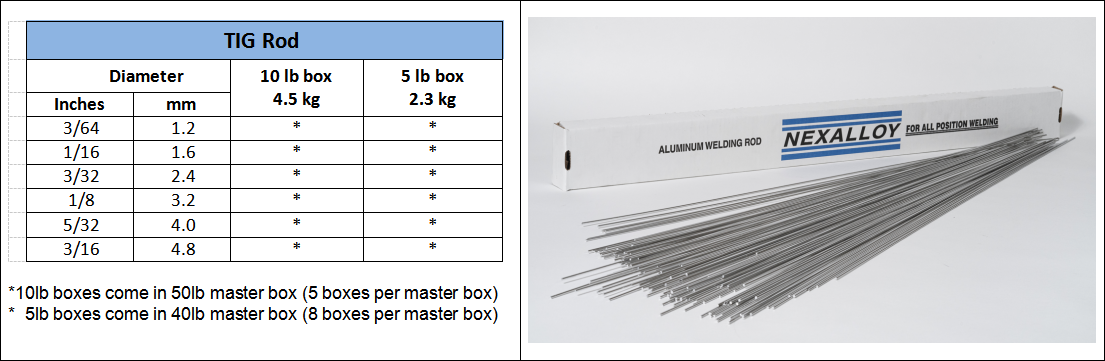

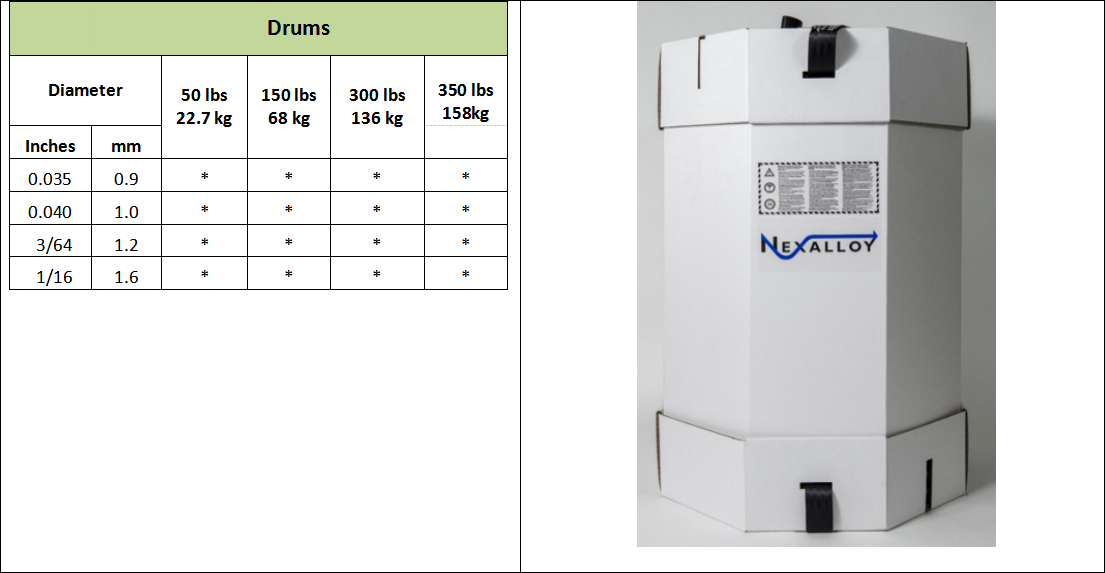

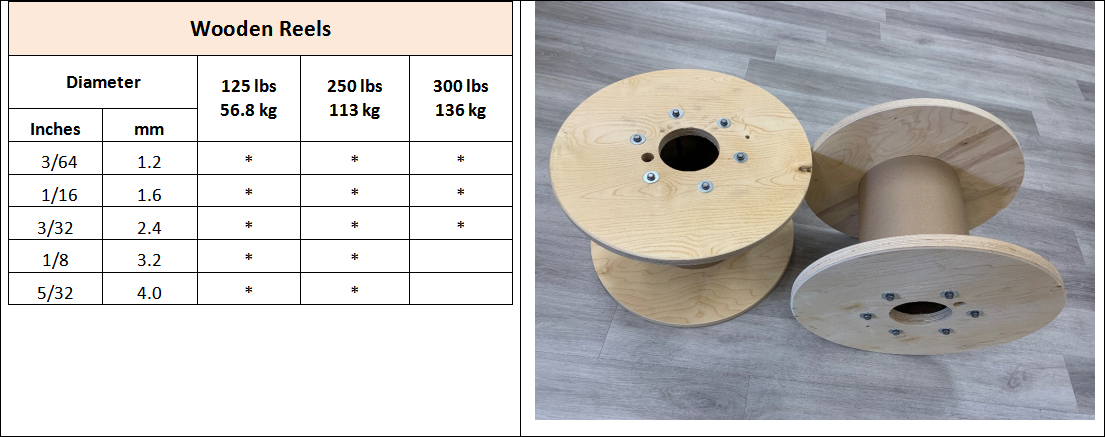

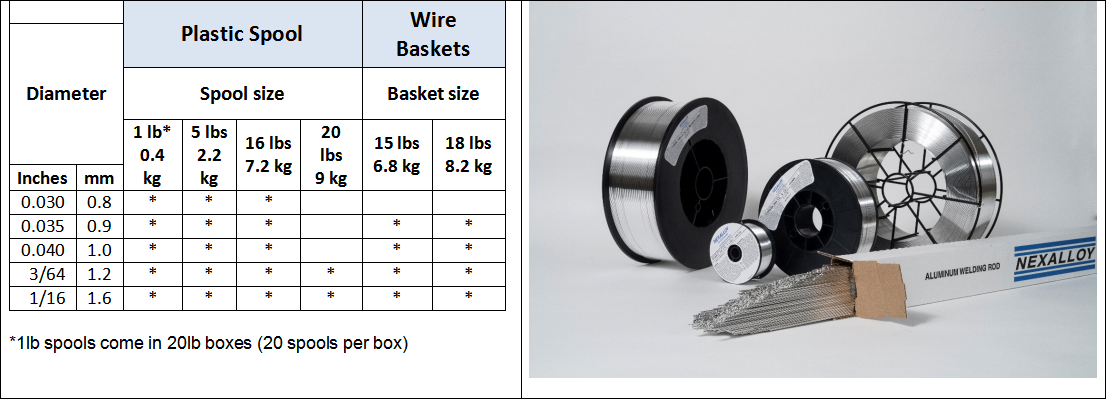

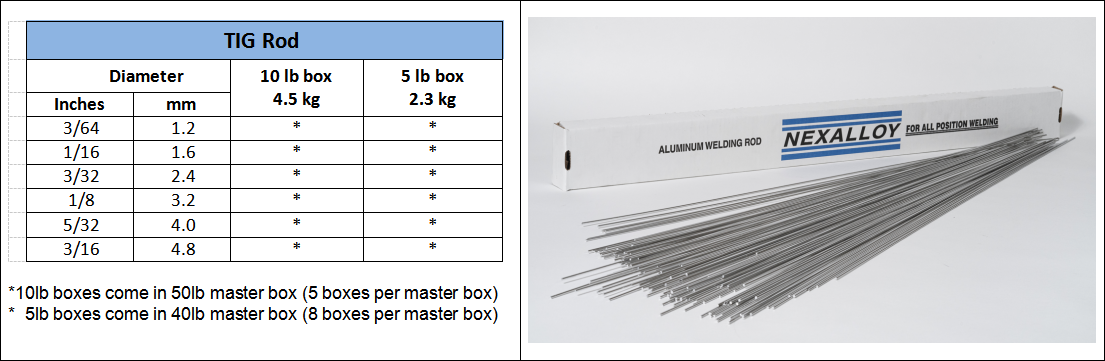

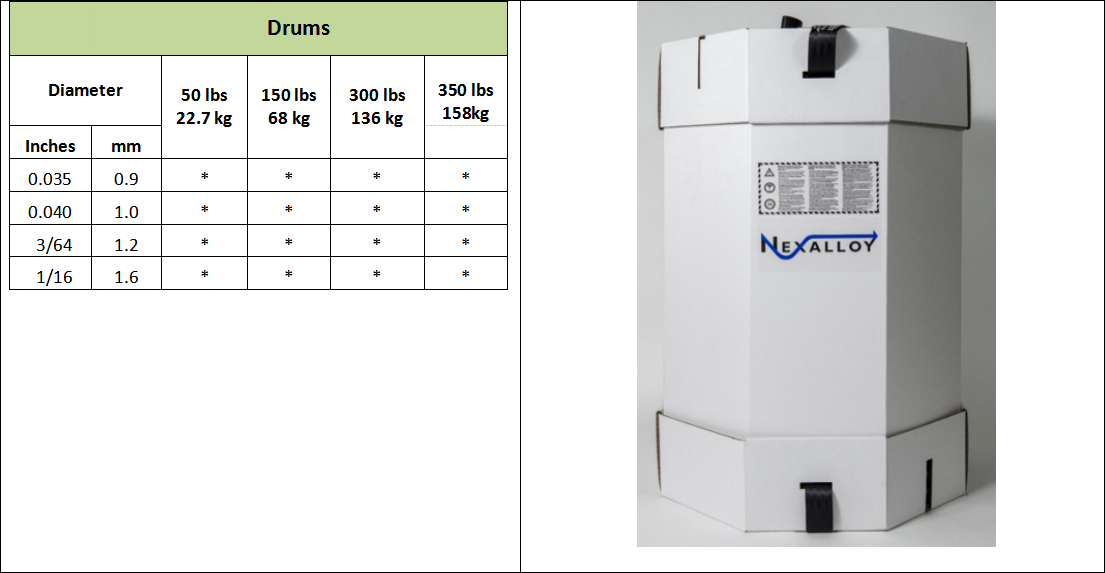

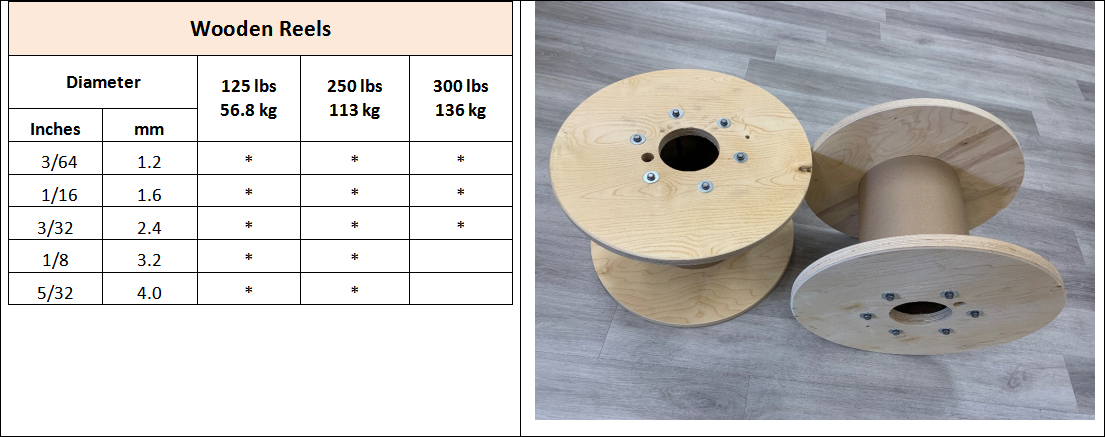

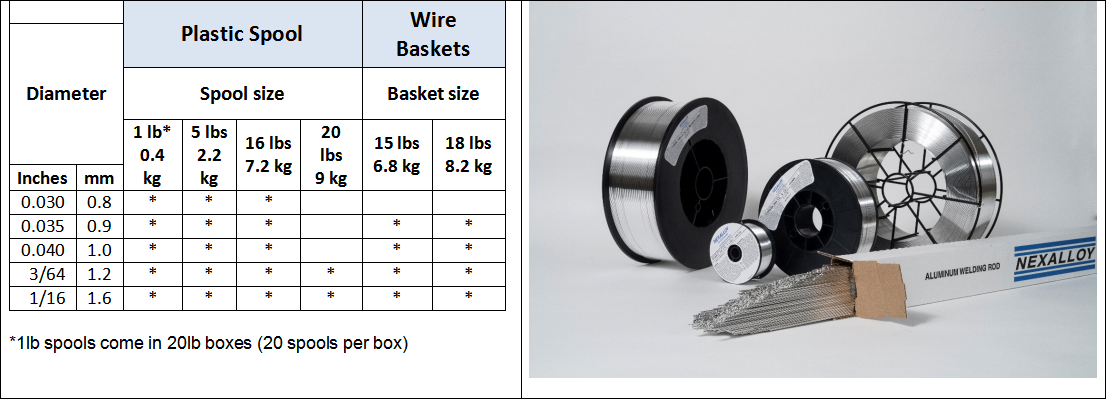

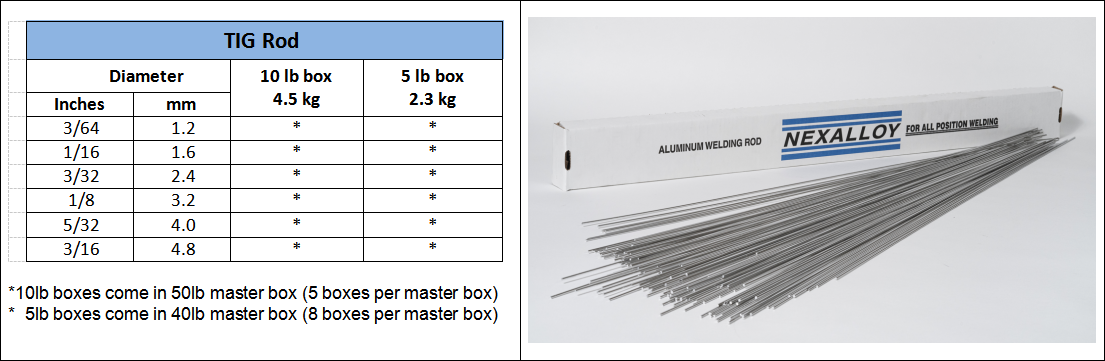

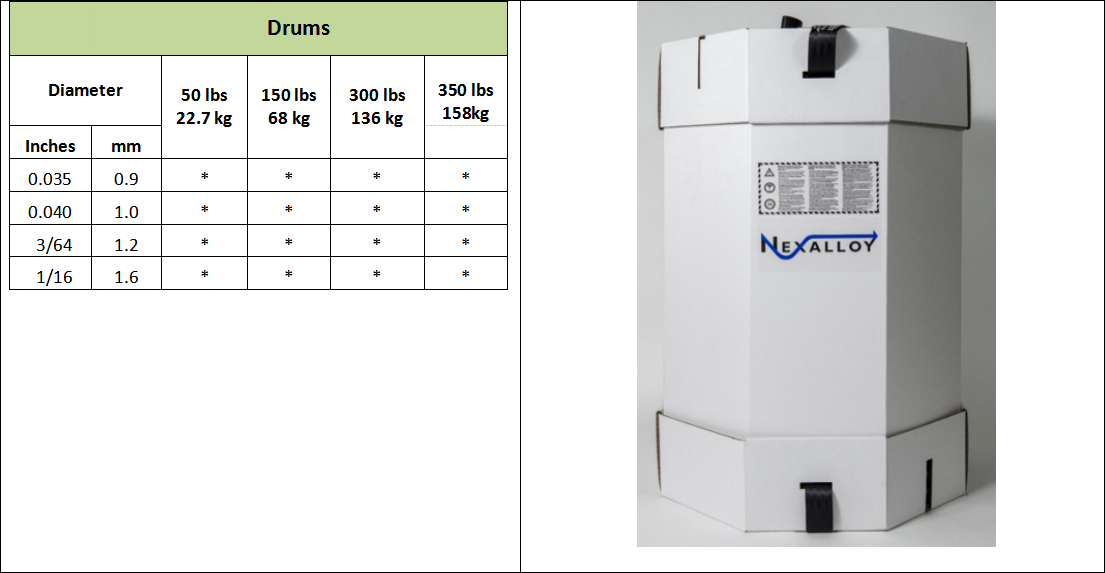

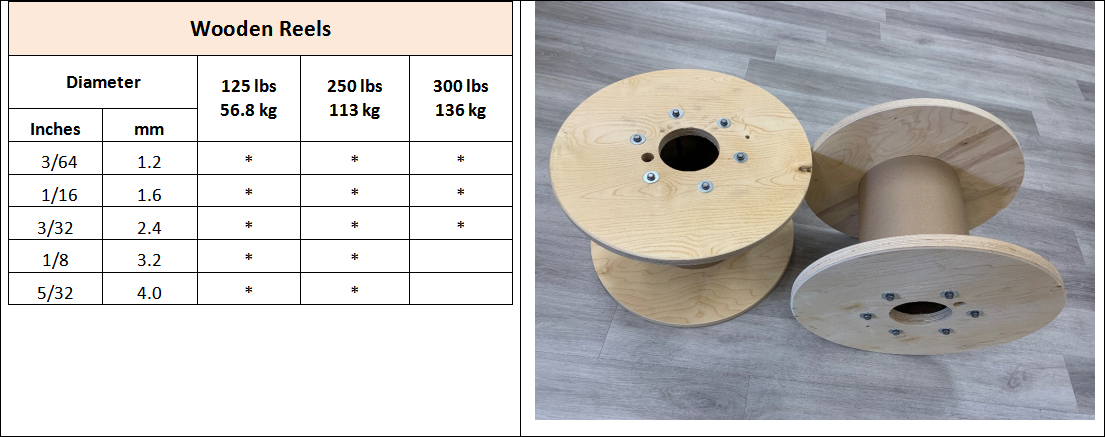

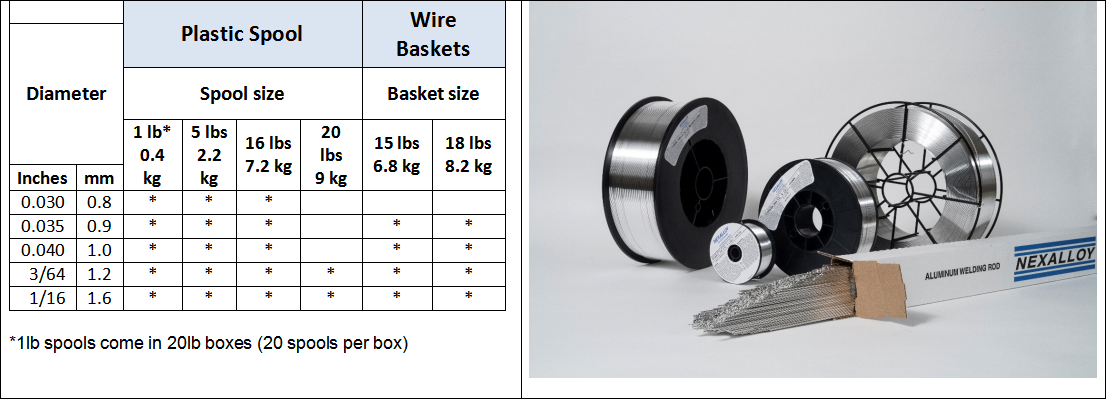

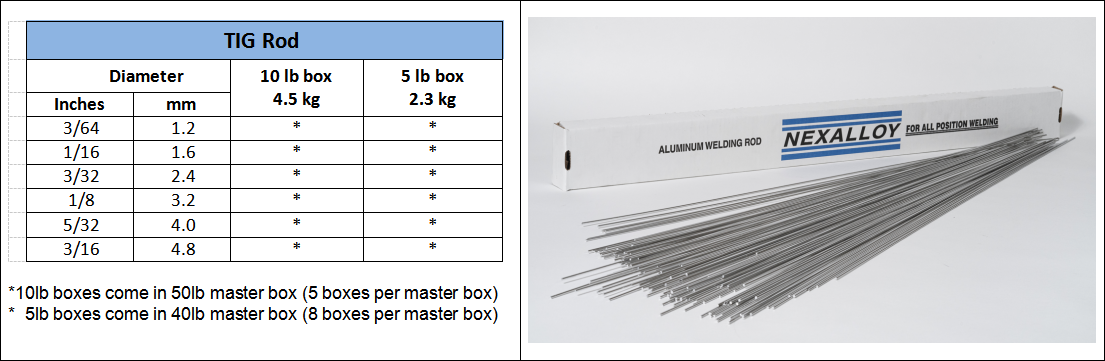

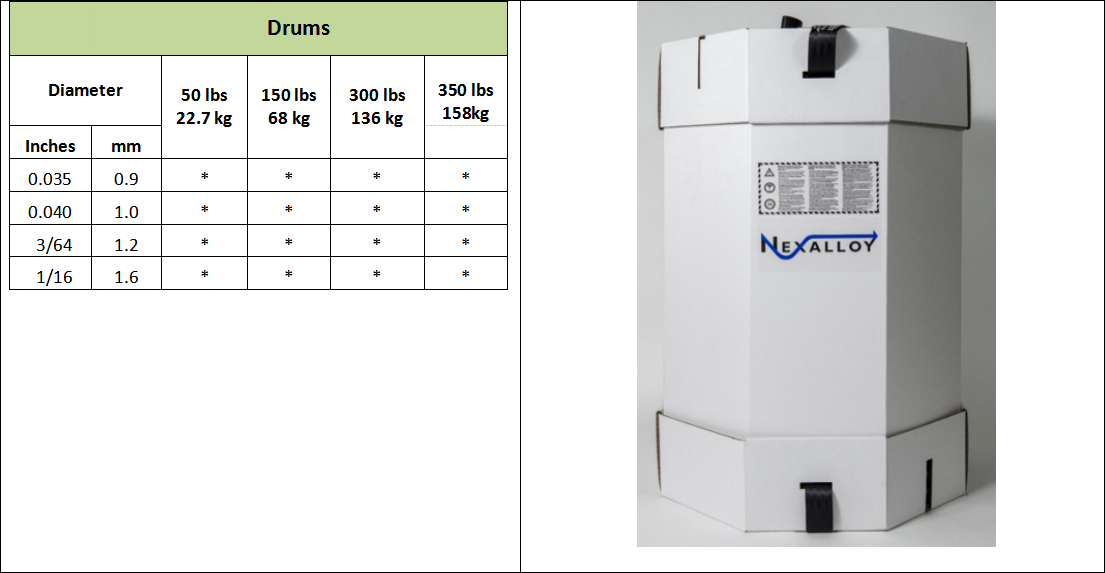

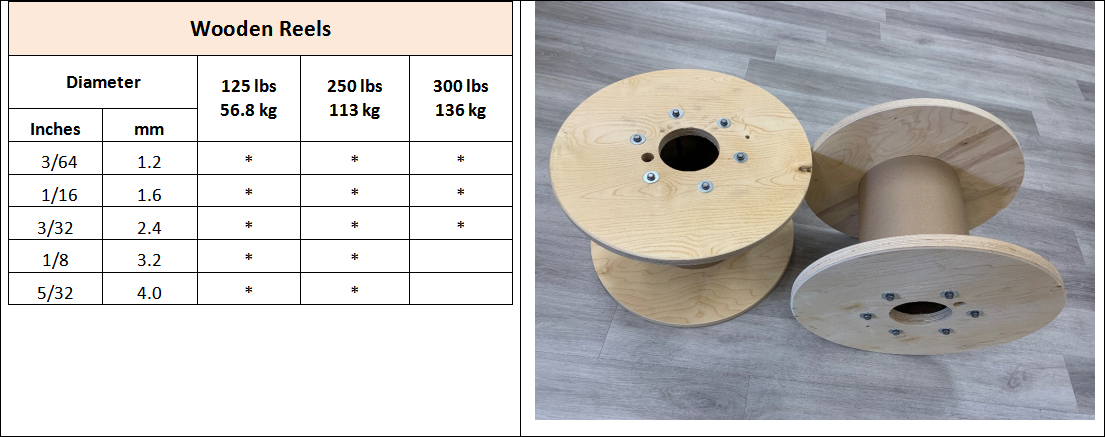

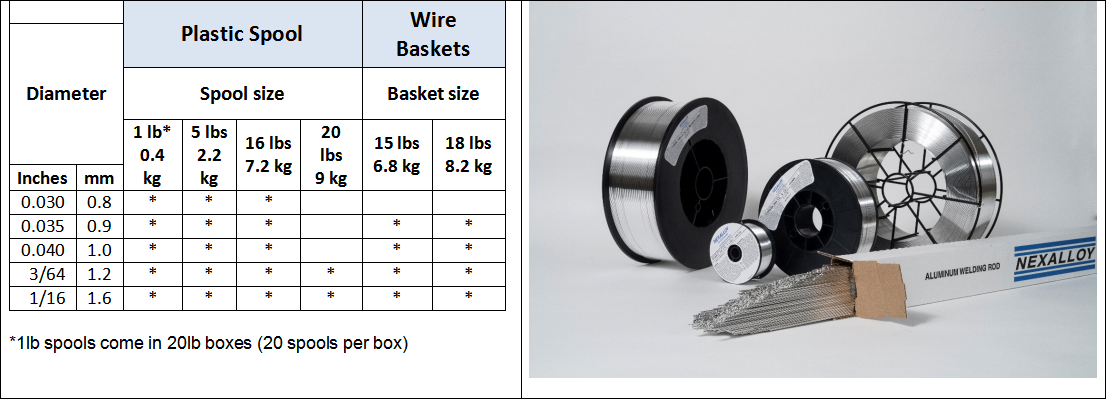

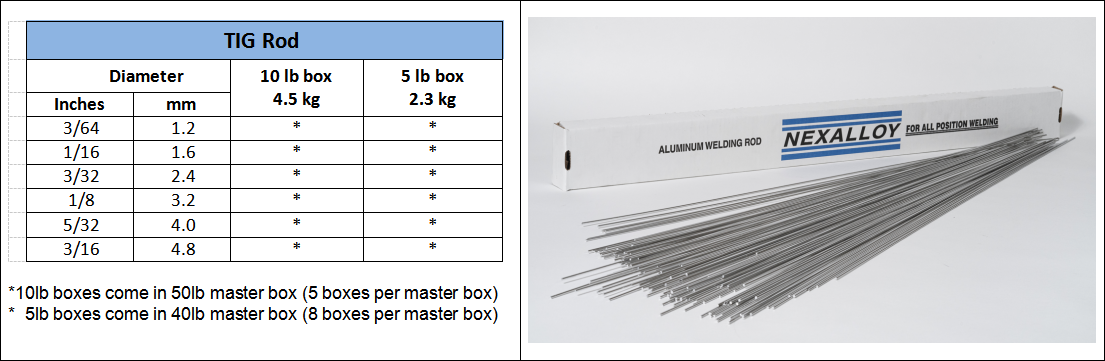

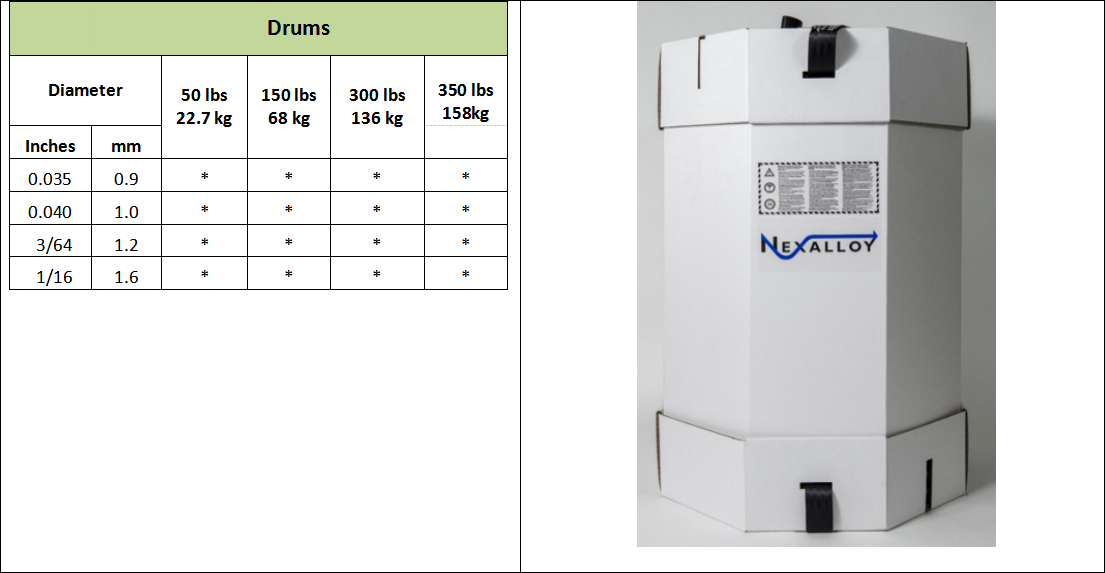

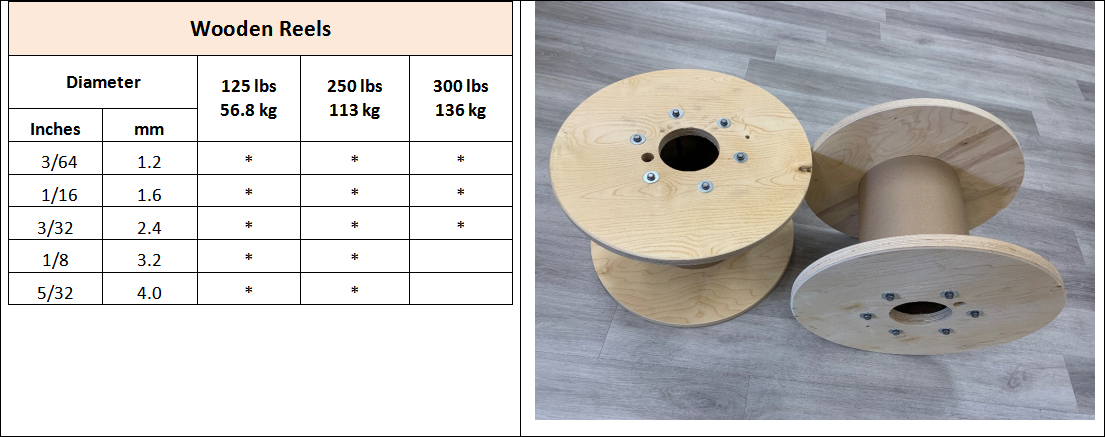

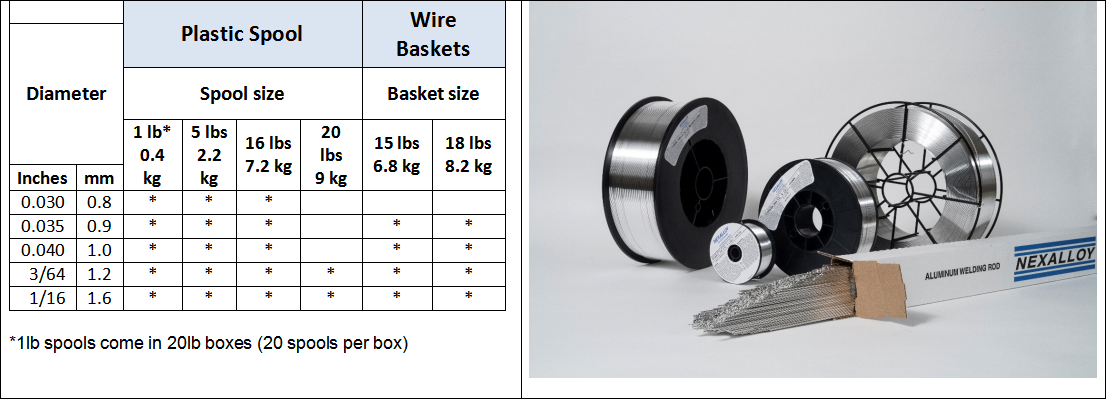

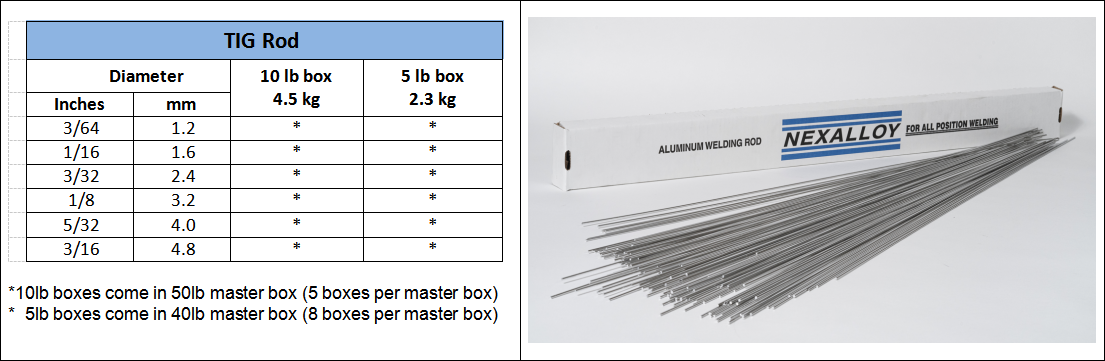

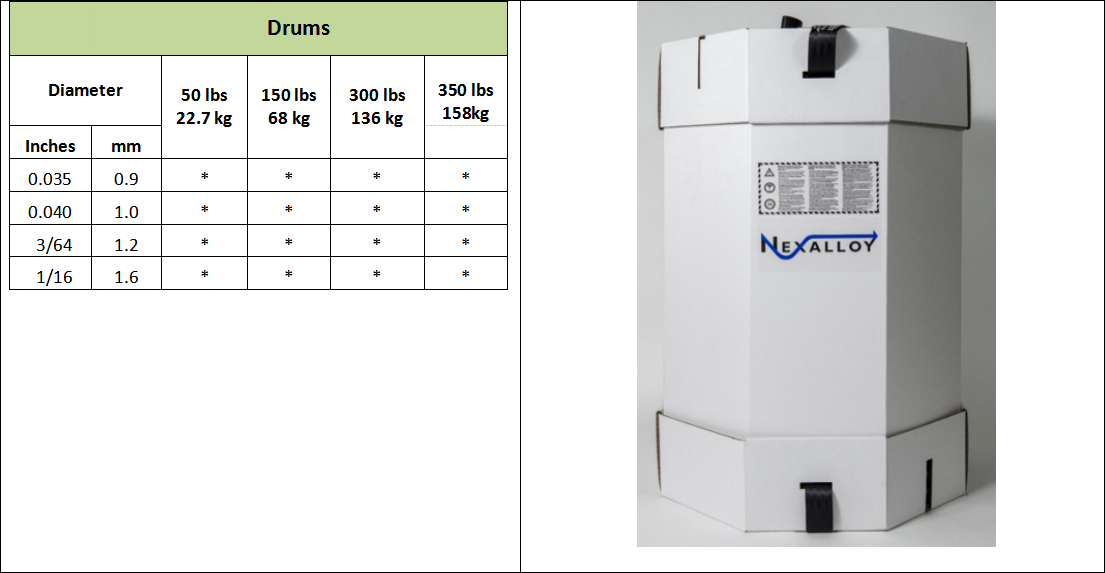

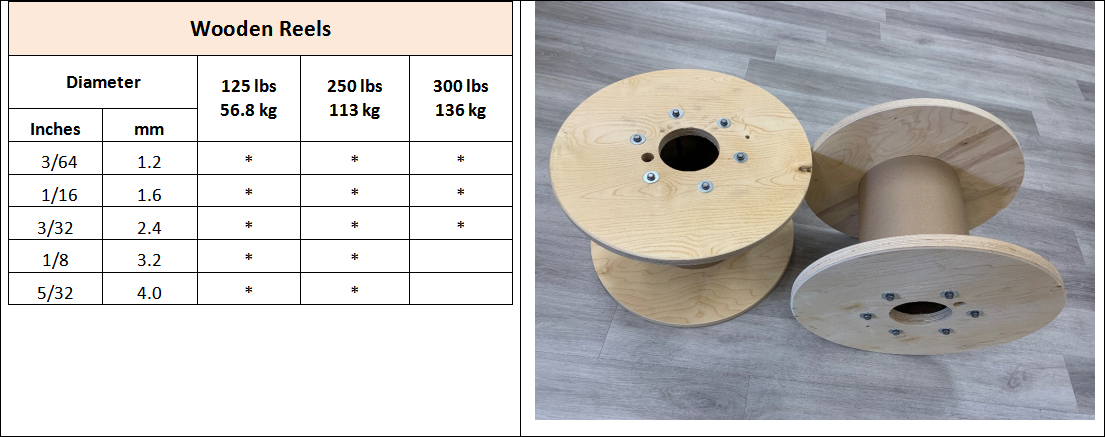

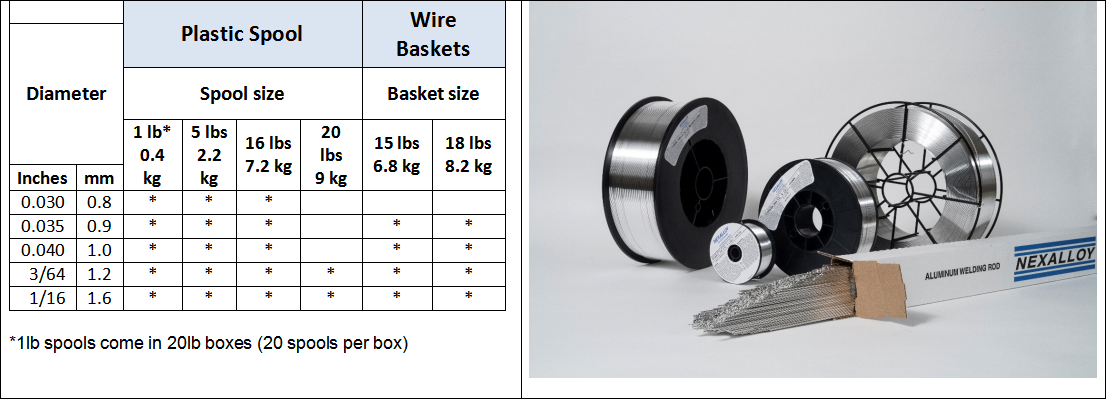

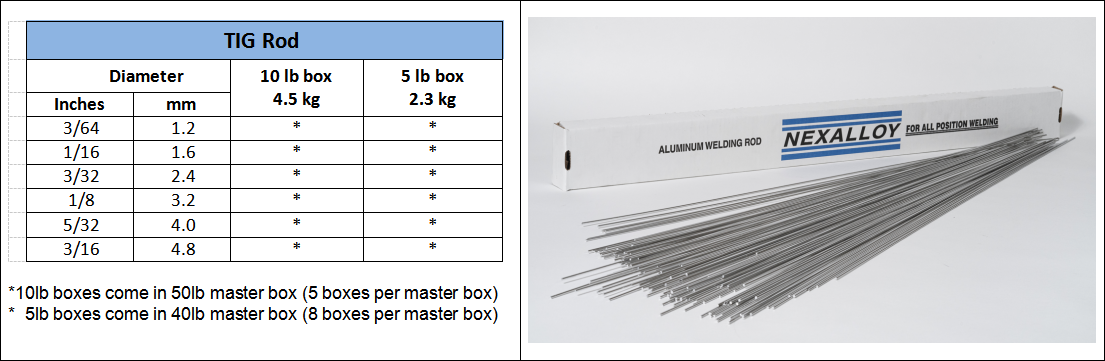

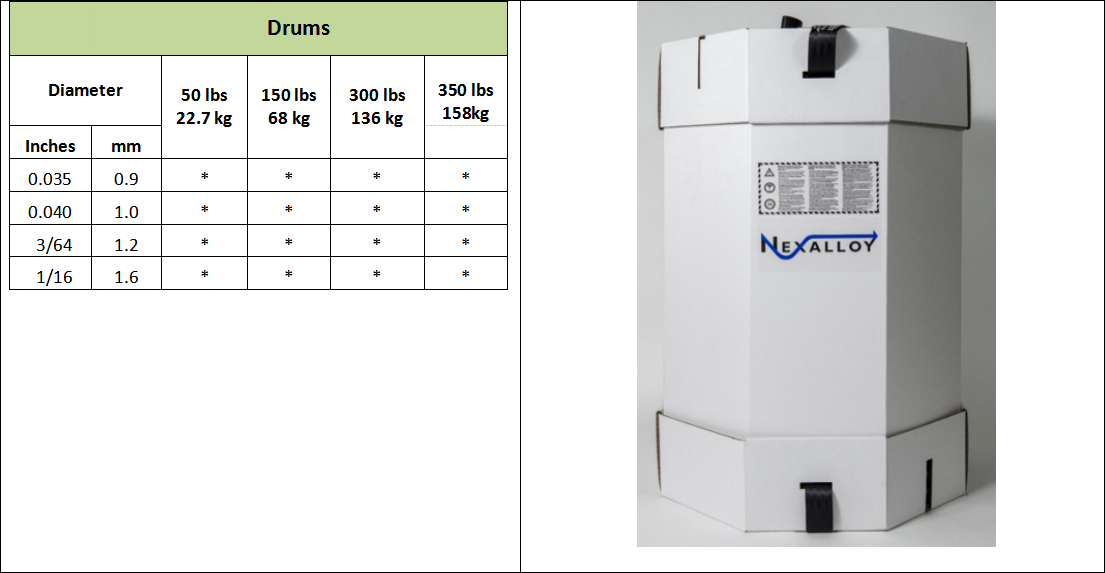

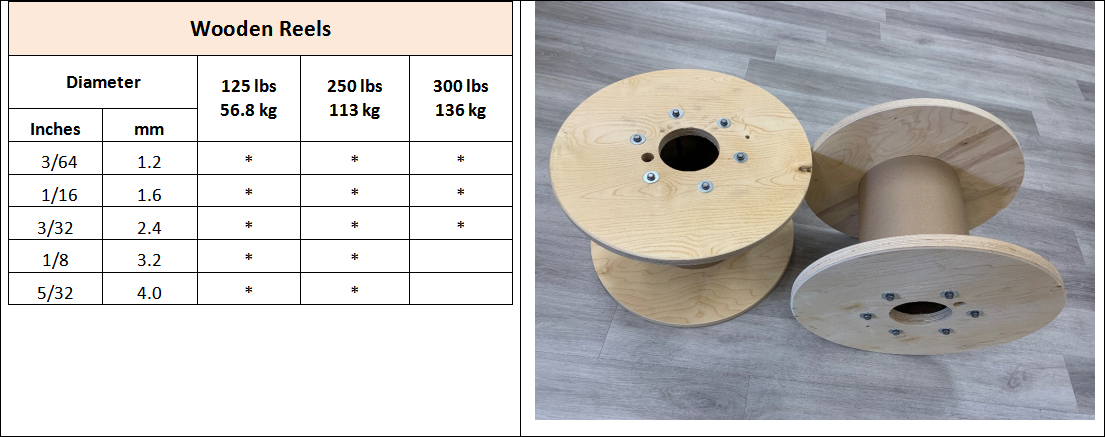

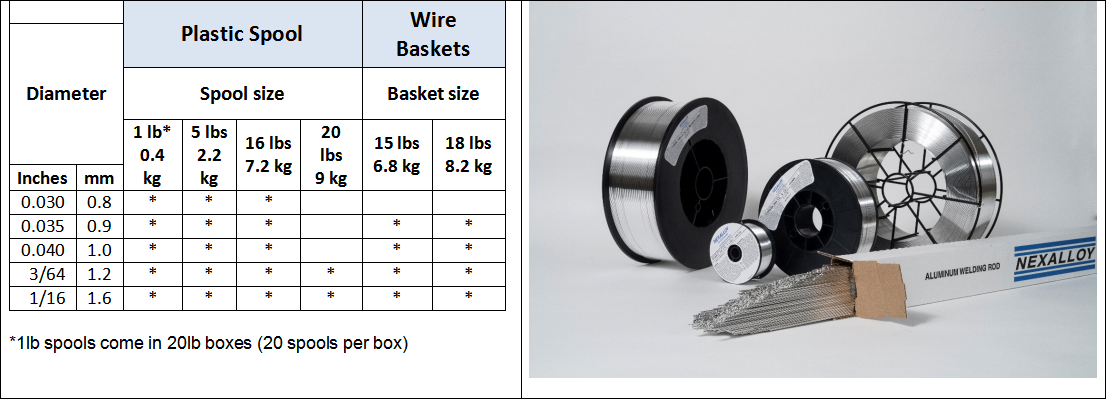

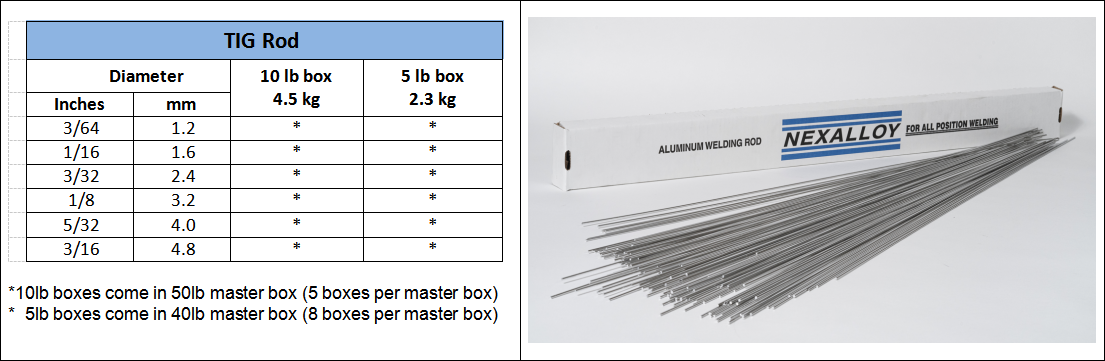

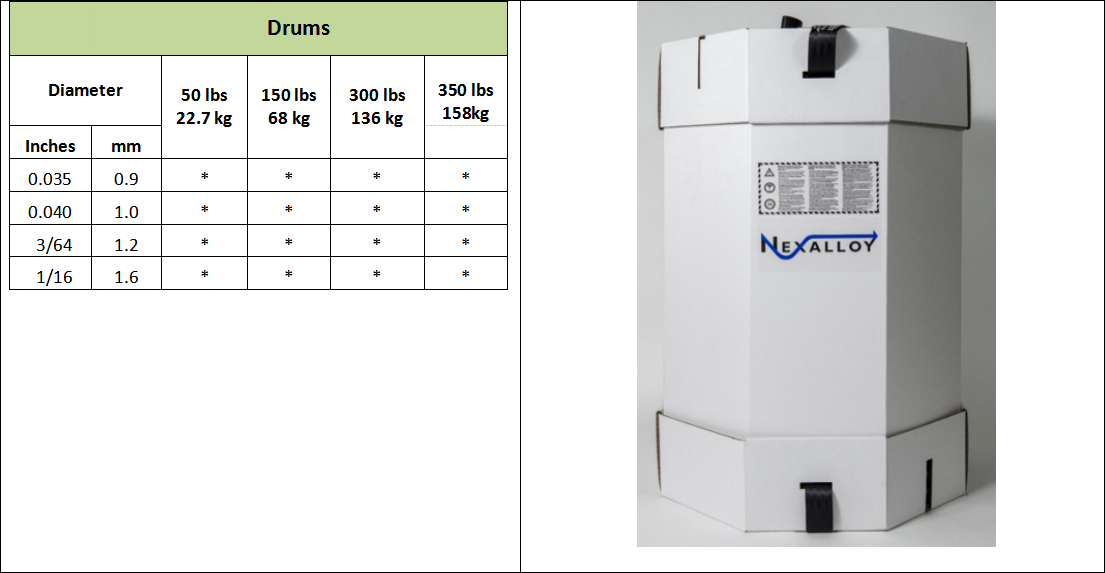

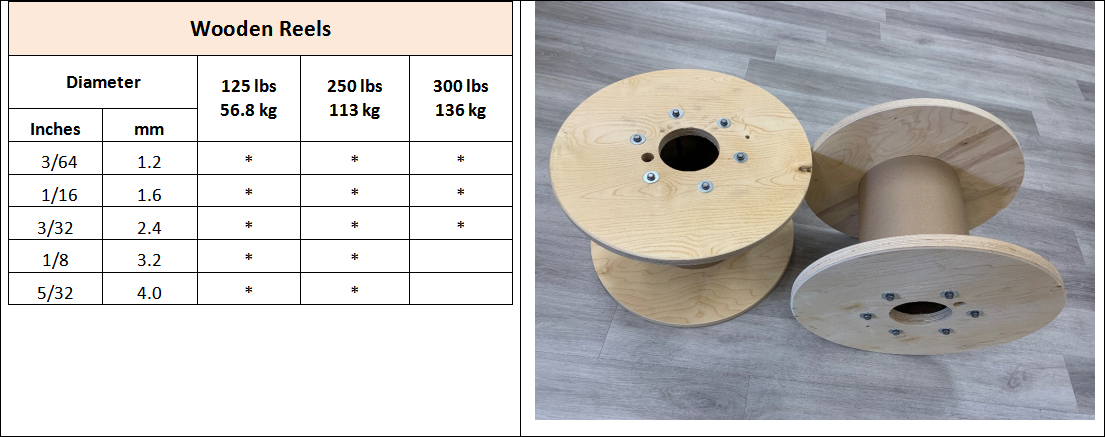

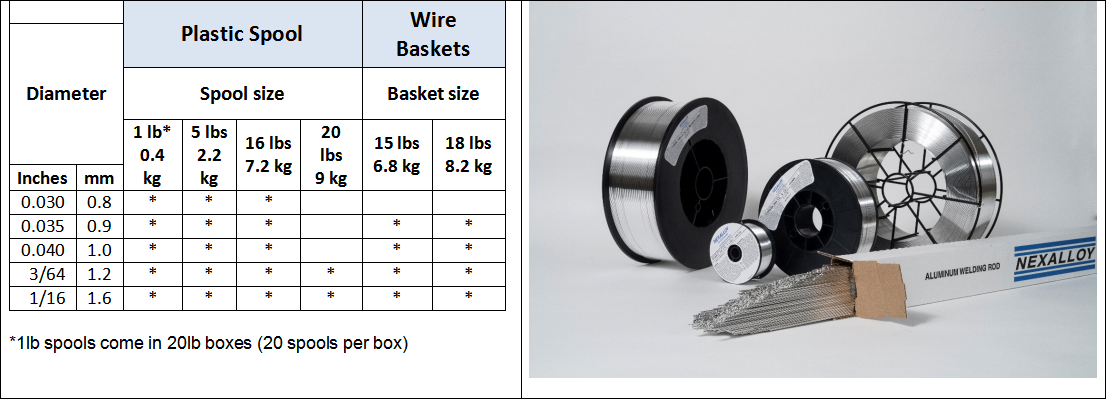

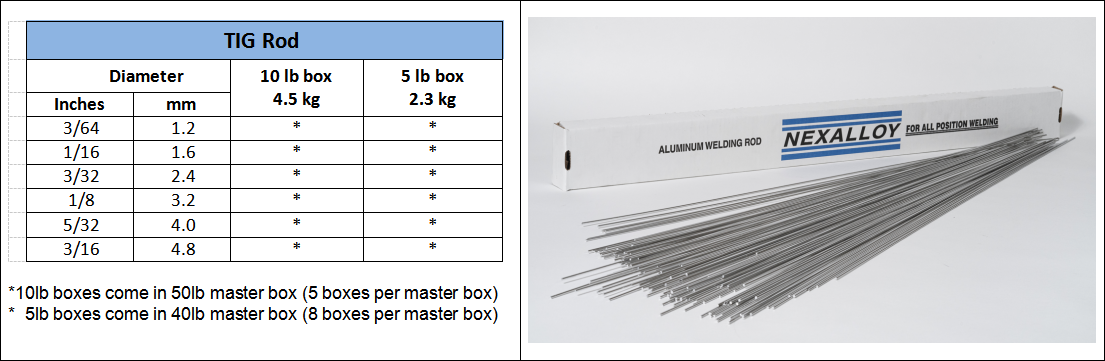

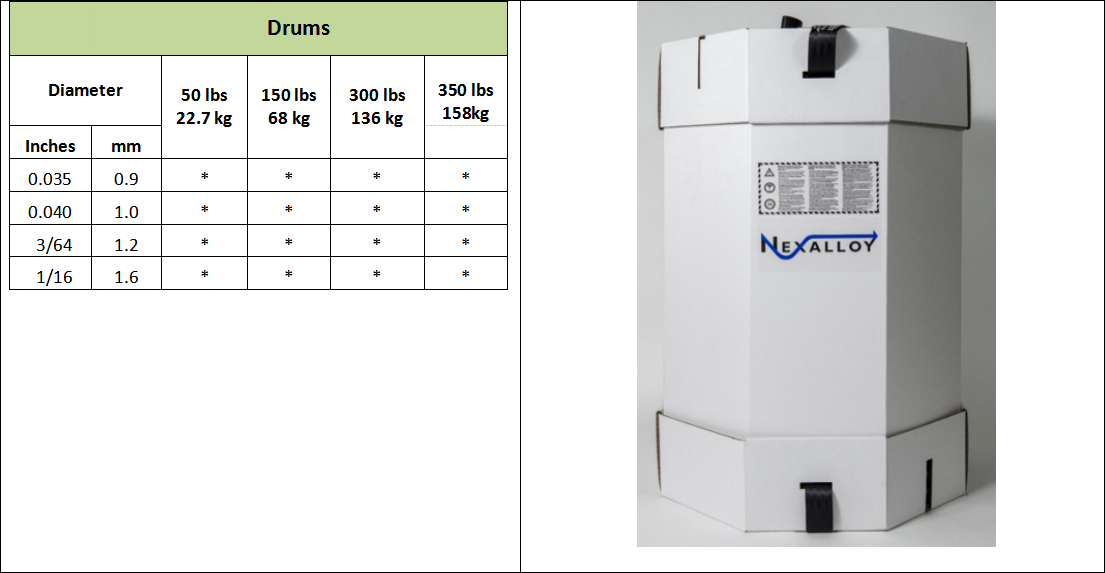

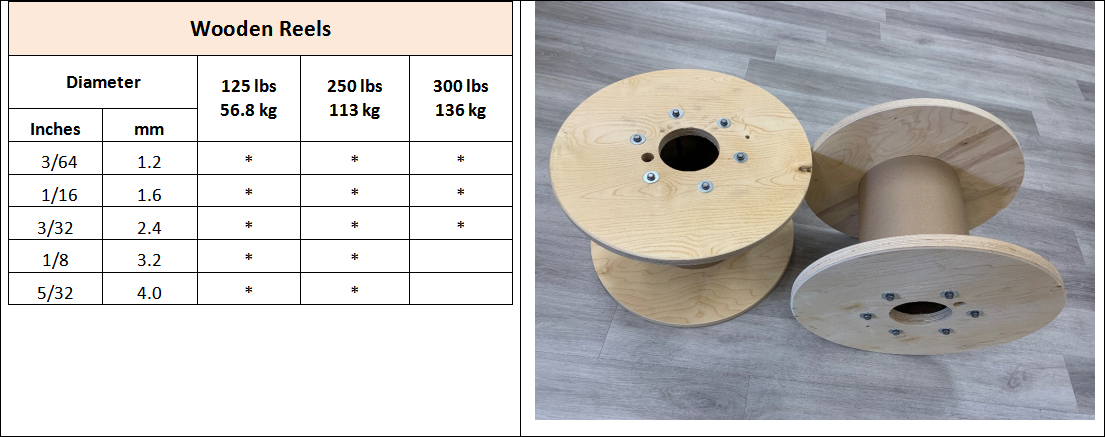

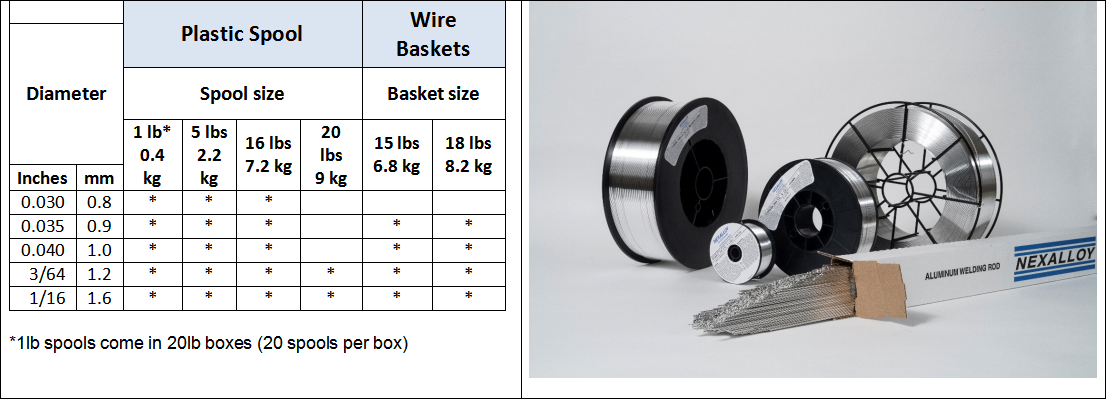

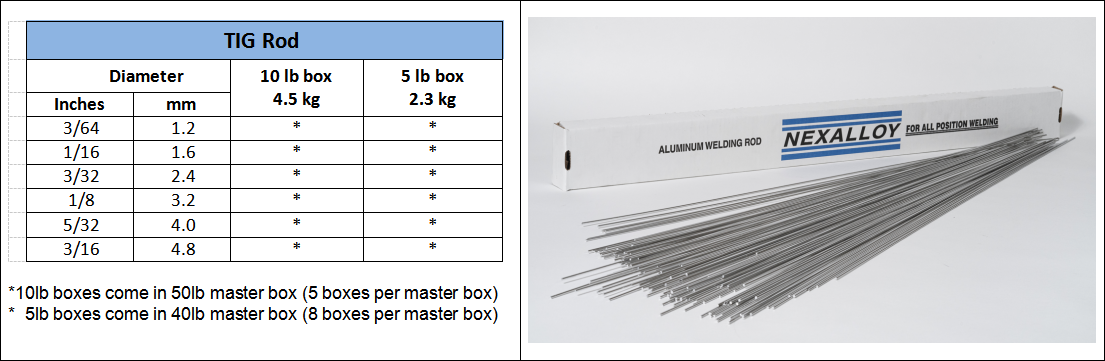

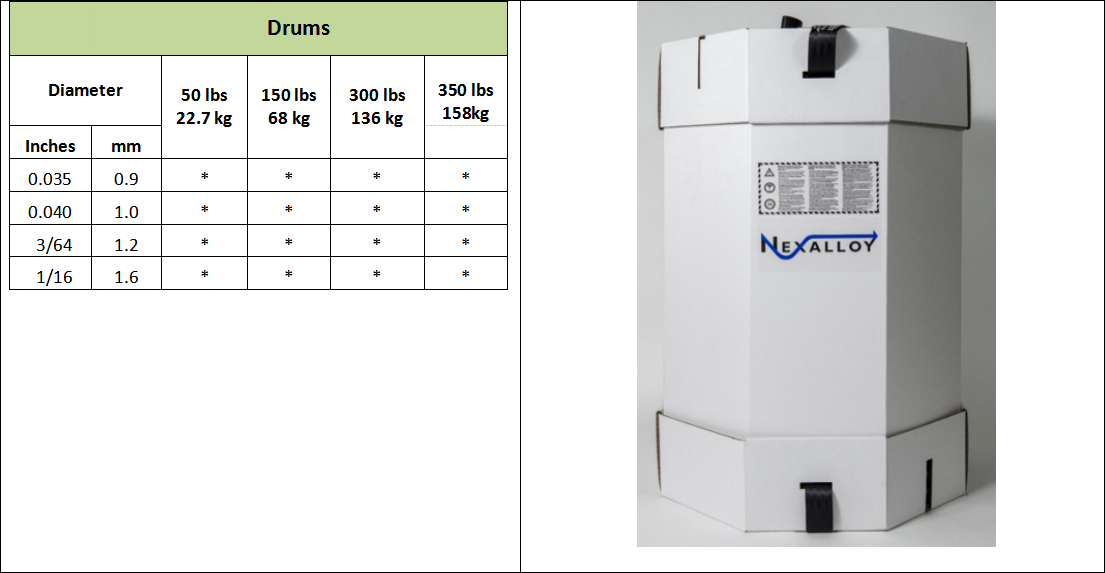

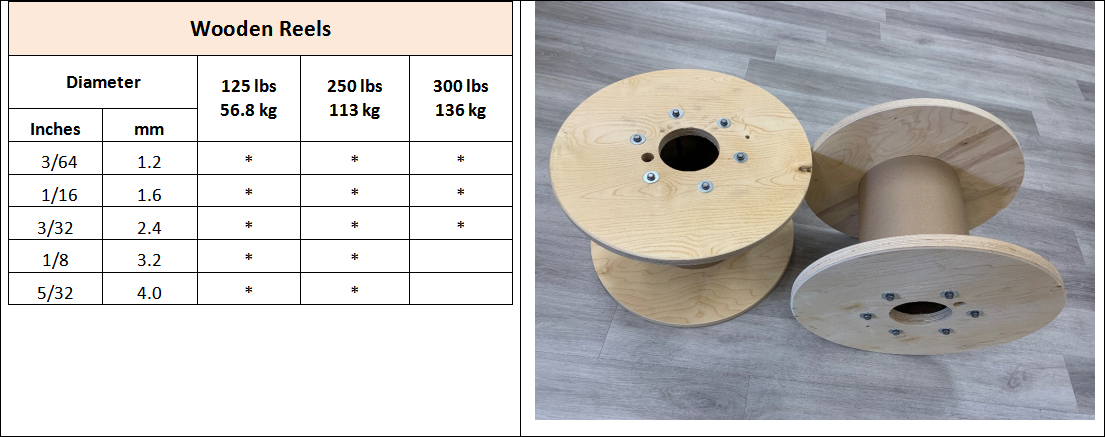

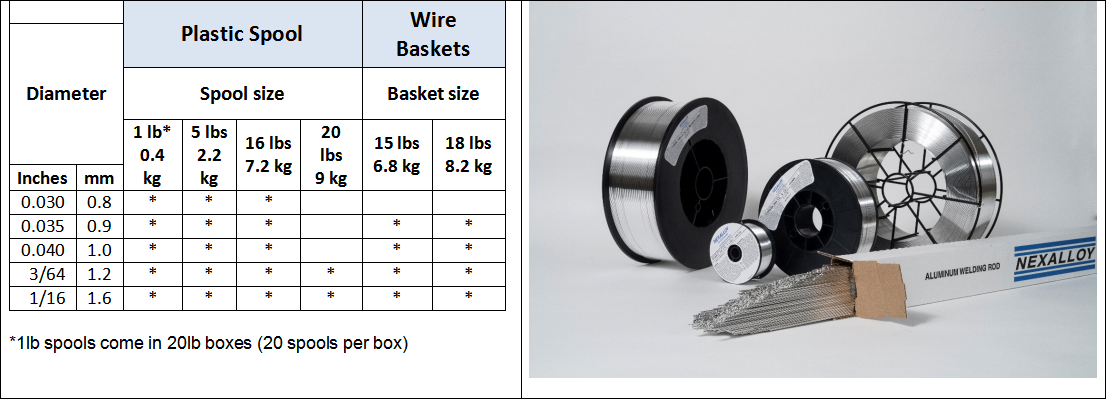

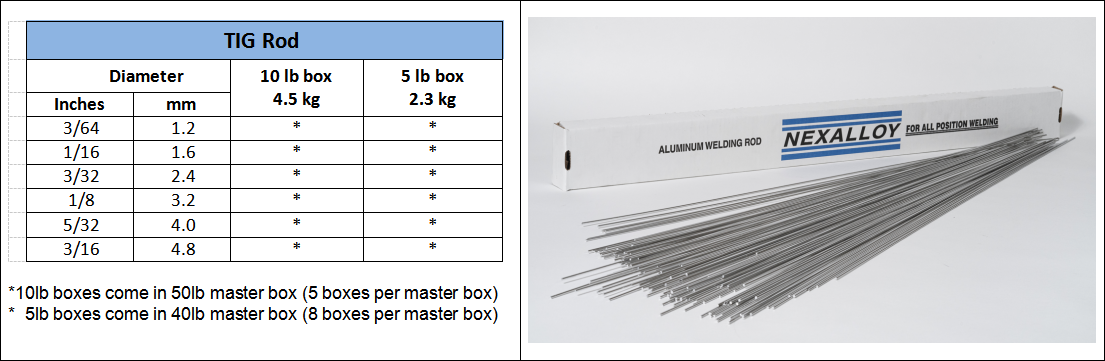

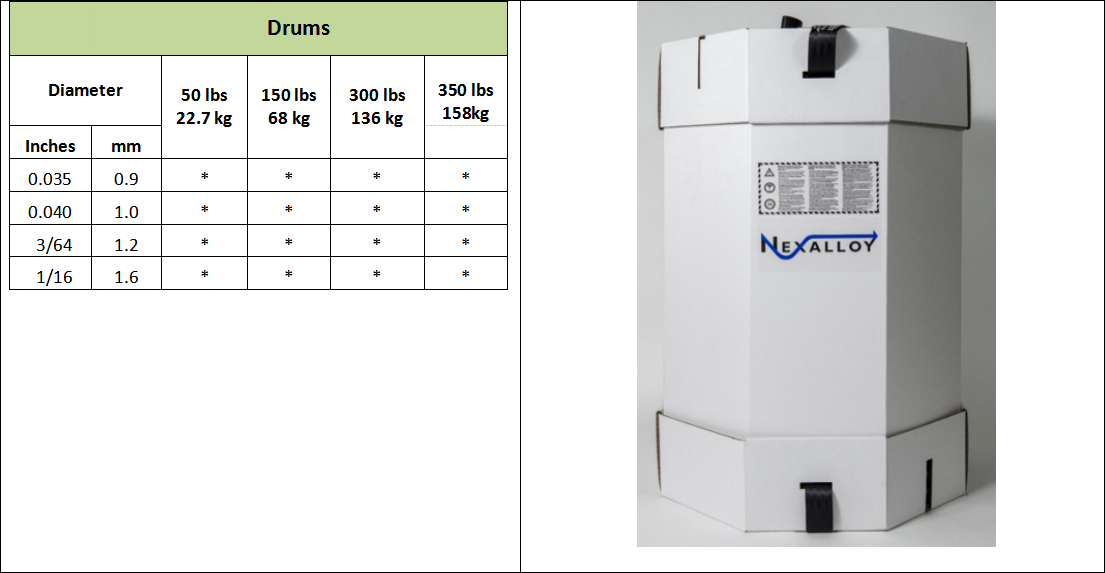

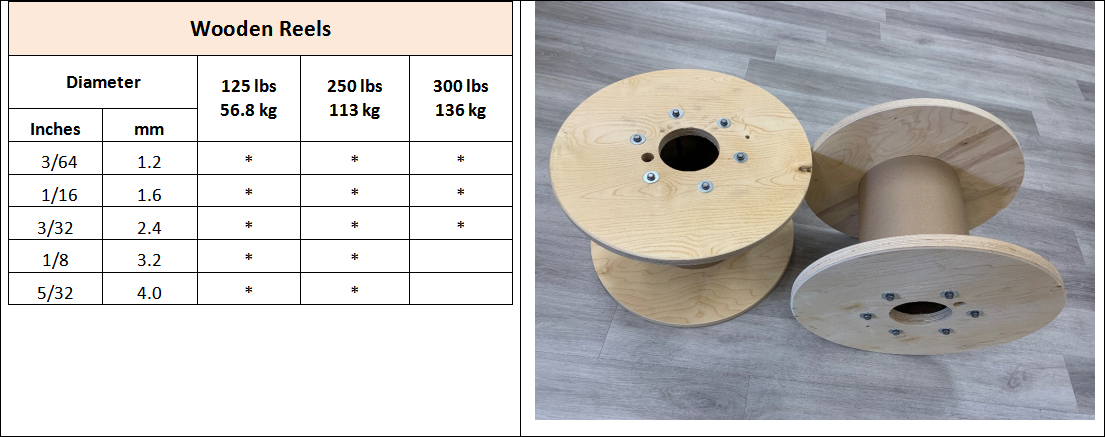

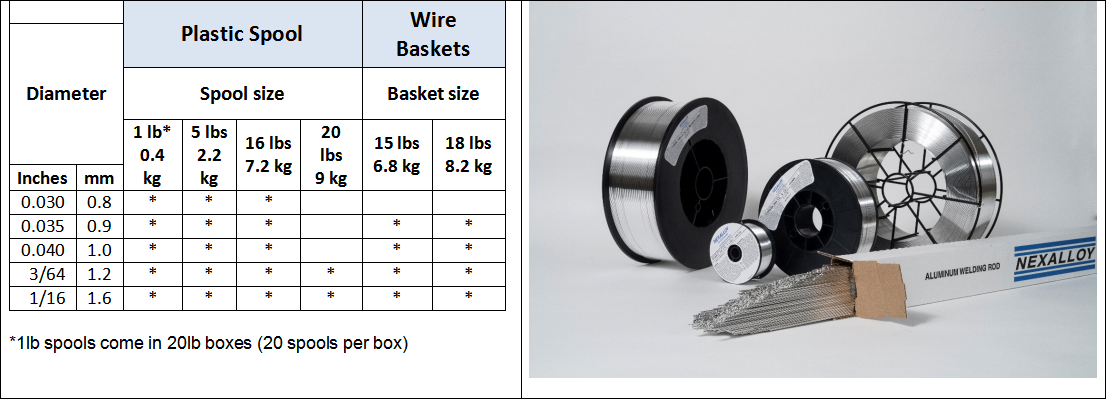

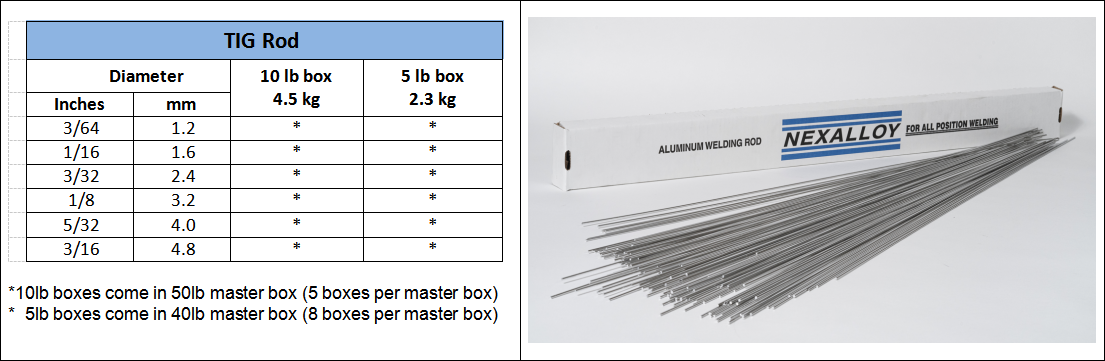

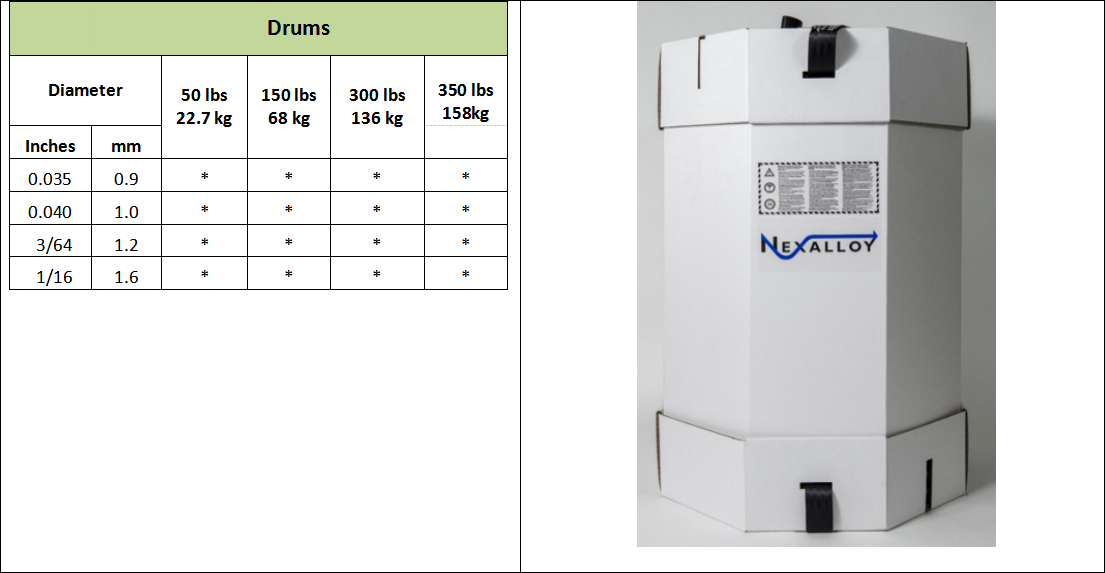

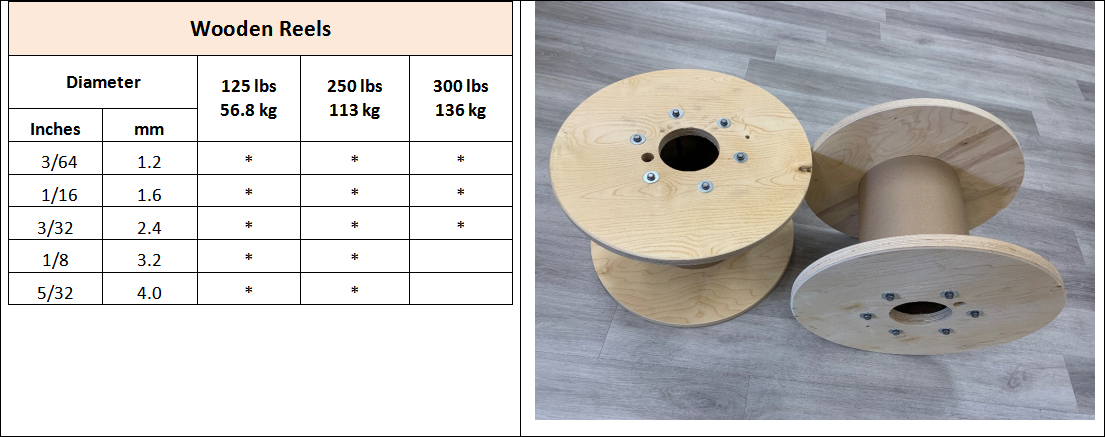

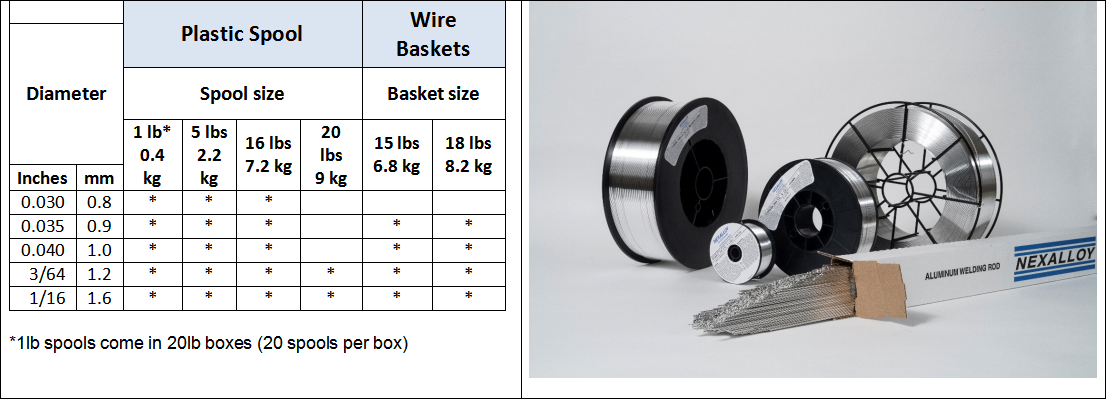

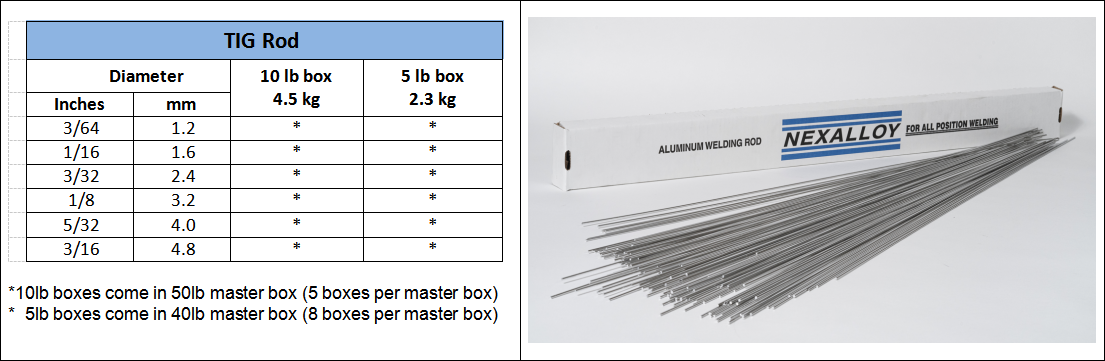

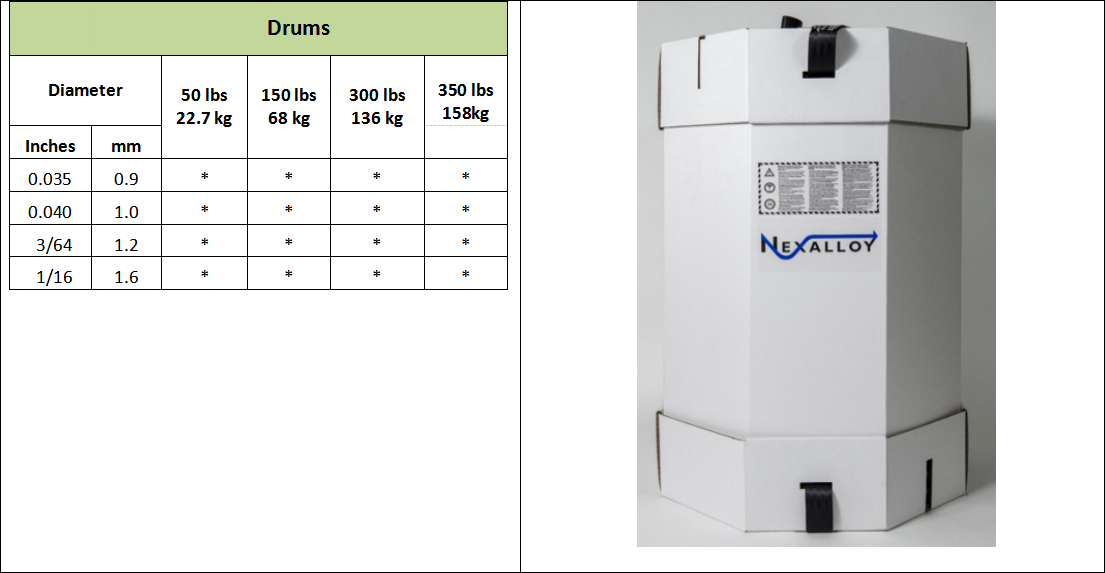

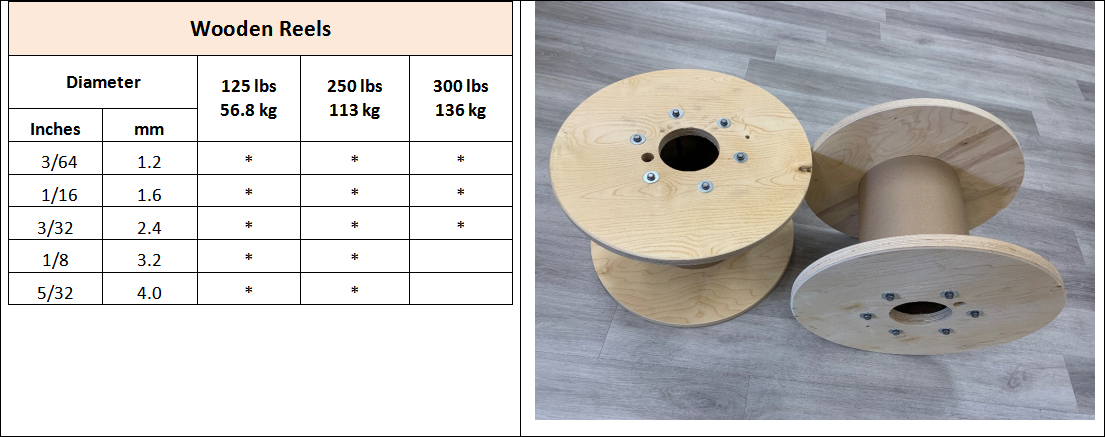

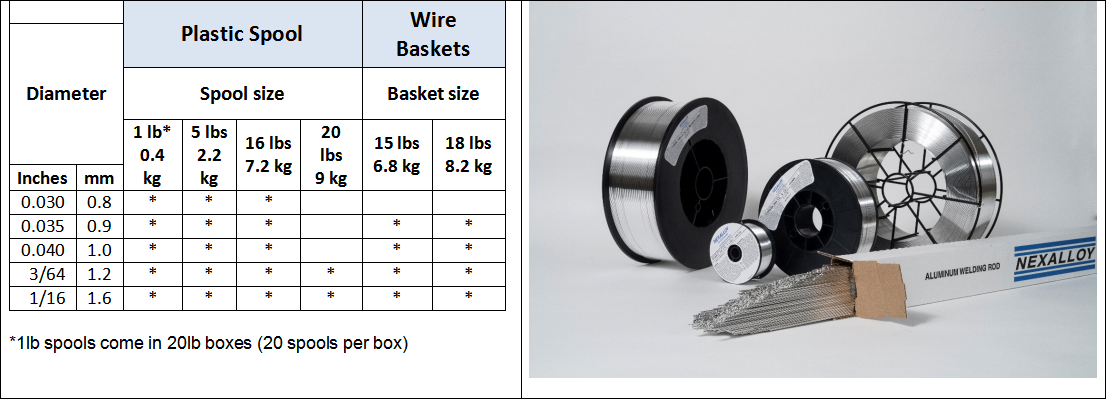

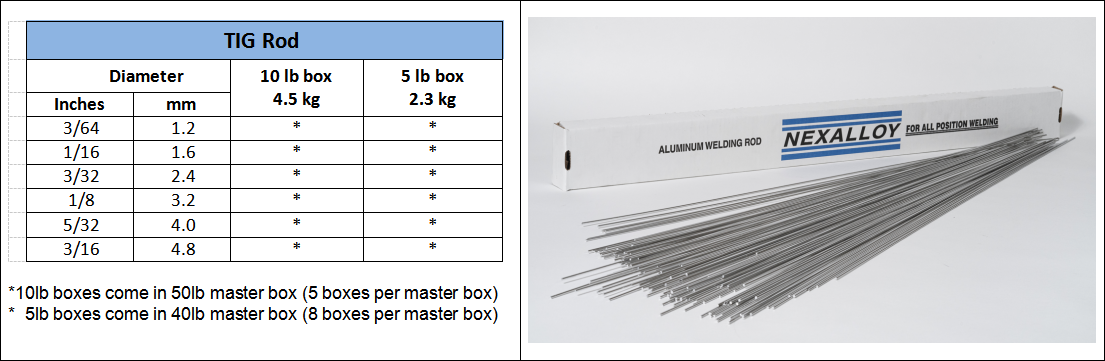

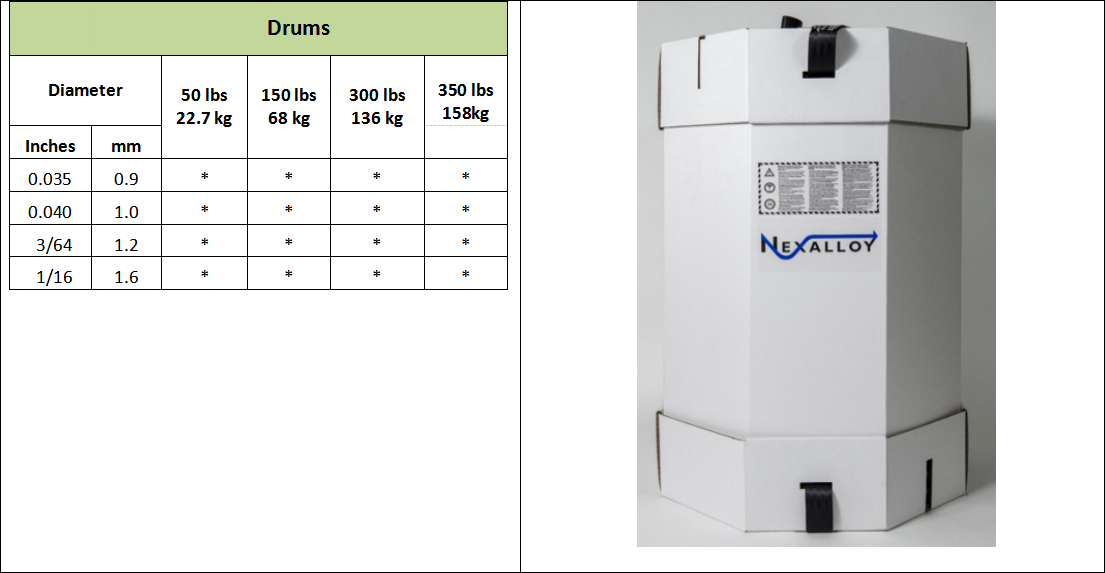

Nexalloy products are available in plastic spools, metal baskets, TIG rods, wooden reels, and drums. Call us for special formats and packaging.

SPECIAL PRODUCTS

Nexal has a complete understanding of the complex metallurgy of aluminum alloys from smelting to final product. Contact us for special aluminum wire products

- NEXALLOY ER1070

- NEXALLOY ER1080A

- NEXALLOY ER1100

- NEXALLOY ER2319

- NEXALLOY ER4043

- NEXALLOY ER4043A/4943

- NEXALLOY ER4047

- NEXALLOY ER5087

- NEXALLOY ER5183

- NEXALLOY ER5356

- NEXALLOY ER5554

- NEXALLOY ER5556

- NEXALLOY ER5754

- NEXALLOY R-357.0

- NEXALLOY R-A356.0

- NEXALLOY R-C355.0

- Metalizing Wire

- TIE WIRE

Interested in One of Our Welding Products?

NEXALLOY ER1070

Nexalloy ER1070 Pure aluminum welding wire containing more than 99.7% aluminum. It provides good electrical conductivity, corrosion resistance and excellent weldability. It is commonly used for the welding of industrial pure aluminum plates and sheets in electronics, construction, and food industries etc.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER1070 conform to: AWS A5.10

DIAMETERS AND PACKAGING

NEXALLOY ER1080A

Nexalloy ER1080A is 99.80% aluminum filler typically used on similar base metal such as 1060, 1070, 1080, 1100, 1350 and 3003.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER1080A conform to: AWS A5.10

DIAMETERS AND PACKAGING

NEXALLOY ER1100

ER1100 is a 99% Aluminum Welding Industry is dominated by filler metal available in spools and cut length for MIG and TIG welding processes. ER1100 is a softer alloy that is commonly used in architectural and decorative applications on furniture and piping, thin gauge materials and foil products. Its softness makes it easy to shape and form giving it an advantage in decorative work and where an attractive weld appearance is critical. Its post anodized color is slightly golden. Typical tensile strength is13.500 psi.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER1100 conform to: AWS A5.10

NEXALLOY ER1100 ADVANTAGES:

- Superior wire surface finish ensures trouble free welding

- Exceptional cleanliness ensures sound weldments

- Unique diameter control for consistent feeding, robotic or manual

DIAMETERS AND PACKAGING

NEXALLOY ER2319

Nexalloy ER2319 is a filler alloy for 2219 base material that is used in high strength structural and aircraft applications where greater resistance to stress corrosion cracking and elevated temperature properties are required. Nexalloy ER2319 is heat treatable and provides higher strength and ductility than 4000 series filler alloys when welding 2000 series alloys.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER2319 conform to: AWS A5.10

DIAMETERS AND PACKAGING

NEXALLOY ER4043

ER4043 is a 5% Silicon aluminum filler metal that is one of the most widely used aluminum welding alloys for fabrication and general repair in the aluminum welding industry. The smooth running ER4043 is often preferred because of its flowing characteristics and its reduced crack sensitivity over other aluminum welding wires. ER4043 is available in spools and cut lengths for both MIG and TIG welding and is recommended for base metals 3003, 3004,5052, 6061, 6063 and casting alloys 43, 355, 356 and 214. ER4043 has a melting range of 1065-1170 Fand a density of .097 lbs/ci. Its post anodizing color is gray.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER4043conforms to: AWS A5.10, CWB

NEXALLOY ER4043 ADVANTAGES:

- All-position MIG welding wire

- Superior wire surface finish ensures trouble free welding

- Superior cleanliness ensures sound weldments

DIAMETERS AND PACKAGING

NEXALLOY ER5087

Nexalloy ER5087 is similar to 5356 with 5% magnesium aluminum filler typically used on similar base metal as 5356 but may give higher tensile strengths on magnesium containing base metals. The alloying element, Zirconium gives improved properties against hot cracking during solidification.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER5087 conform to: AWS A5.10

DIAMETERS AND PACKAGING

NEXALLOY ER4043A/4943

Nexalloy 4043A/4943 is an alternative alloy to 4043 with 25% higher Ultimate Tensile Strength (UTS) and 50% higher yield strength in the as welded condition. Similar to 4043 it possesses moderate to high strength (35 ksi typical), low melting temperature and high fluidity, low ductility, formability and lower toughness as well as moderate electrical and thermal conductivity. 4043A/4943 may be used to weld 1XXX, 3XXX, 5XXX with less than 3.0% Mg. Common applications include automotive frames, aerospace hardware, bicycles, concrete forms and furniture.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER4043A/4943 conforms to: AWS A5.10

NEXALLOY ER4043A/4943 ADVANTAGES:

- All-position MIG welding wire

- Superior wire surface finish ensures trouble free welding

- Superior cleanliness ensures sound weldments

DIAMETERS AND PACKAGING

NEXALLOY ER4047

ER4047 is an aluminum welding alloy with a 12% silicon content. Originally formulated for brazing, its features are high fluidity, narrow freeze range, low melting range and low shrinkage. ER4047 is a good general purpose, free flowing filler metal with good corrosion and hot cracking resistance when welded. It can also be used in sustained elevated temperatures. It comes in spools and cut length for MIG, TIG and brazing applications on 1060,1350, 3003, 3004, 3005,5005, 5050, 6053, 6061, 6951, 7005 and cast alloys 710.0 and711.0.ER4047 has a melting range of 1070- 1080° F and a density of 0.96 lbs/ci. Its typical tensile strength is 27, 500 psi and its post anodized color is gray-black.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER4047 conforms to: AWS A5.10, CWB

NEXALLOY ER4047 ADVANTAGES:

- Superior wire surface finish ensures trouble free welding

- Exceptional cleanliness ensures sound weldments

- Unique diameter control for consistent feeding, robotic or manual

DIAMETERS AND PACKAGING

NEXALLOY ER5183

ER5183 is an aluminum filler metal containing higher levels of manganese, magnesium and chrome. ER5183 Is formulated to provide the highest possible “as-welded” strength in high magnesium alloys. Available in spools and cut length for MIG and TIG applications. ER5183 is known for its high fracture and impact toughness and exposure to corrosive elements. Applications include marine components, drilling rigs, cryogenics, etc. Base metals include 5083, 5086 and 5456 to similar base metals or to 5052, 5652 and 5056. Its melting range is 1075-1 180•F, its density Is 0.96 lbs/ci. The typical tensile strength is 41,000 psi and the post anodizing color is white.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER5183 conforms to: AWS A5.10, CWB, and ABS

NEXALLOY ER5183 ADVANTAGES:

- Superior wire surface finish ensures trouble free welding

- Exceptional cleanliness ensures sound weldments

- Unique diameter control for consistent feeding, robotic or manual

DIAMETERS AND PACKAGING

NEXALLOY ER5356

ER5356 is a 5% magnesium aluminum filler metal, available in spools and cut length for both MIG and TIG applications. ER5356 has increased levels of Mg, Ti and Mn along with the addition of chrome and a slight reduction in silicon. These changes work together to increase its corrosion resistance, making it the best aluminum for use in or near saltwater.ER5356 is commonly used on 5050, 5052, 5083, 5356, 5454 and 5456 and is the second most widely used aluminum filler metal. ER5356 has a melting range of 1060-1175F, a density of 0.96 lbs/ci and a typical tensile strength of 38,000 psi. Its post anodizing color is white.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER5356 conforms to: AWS A5.10, CWB, and ABS

NEXALLOY ER5356 ADVANTAGES:

- Superior wire surface finish ensures trouble free welding

- Exceptional cleanliness ensures sound weldments

- Unique diameter control for consistent feeding, robotic or manual

DIAMETERS AND PACKAGING

NEXALLOY ER5554

Nexalloy ER5554 is an aluminum filler typically used on 5454 and similar base metal that may be used in transportation applications such as over-the-road trailers and rail tank cars chemical tanks and other storage where temperatures above 150F may be found.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER5554 conforms to: AWS A5.10

NEXALLOY ER5554 ADVANTAGES:

- Superior wire surface finish ensures trouble free welding

- Exceptional cleanliness ensures sound weldments

- Unique diameter control for consistent feeding, robotic or manual

DIAMETERS AND PACKAGING

NEXALLOY ER5556

ER5556 is an aluminum filler metal with higher level s of manganese, zinc and magnesium than ER5356, giving ER5556 increased crack resistance and good ductility. Available in MIG and TIG forms.While tensile strengths are among the highest in aluminum filler metals, the higher magnesium content can decrease its resistance to stress corrosion cracking in prolonged temperatures above 150°F. Commonly used on5154, 5254, 5454 and 5456.ER5556 has a melting range of 1065-1175°F, and has a density of 0.96 lbs/ci. Its typical tensile strength is 42,000 psi and the postanodizing color is white.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER5556 conforms to: AWS A5.10, CWB, ABS

NEXALLOY ER5556 ADVANTAGES:

- Superior wire surface finish ensures trouble free welding

- Exceptional cleanliness ensures sound weldments

- Unique diameter control for consistent feeding, robotic or manual

DIAMETERS AND PACKAGING

NEXALLOY ER5754

Nexalloy ER5754 is an Aluminum-alloyed wire for welding of aluminum alloys up to 3% Mg. Good corrosion resistance and excellent color match after anodizing. The weld metal is seawater resistant. ER5754 is suitable for a wide range of applications in general construction and structural industry like Automotive, Storage tank and Shipbuilding.

- MIG / TIG

- Available in all standard diameters and packaging

- Nexalloy ER5754 conform to: AWS A5.10

DIAMETERS AND PACKAGING

NEXALLOY R-357.0

Nexalloy R-357.0 is a high purity Aluminum casting which is similar to alloy R-A356.0, but it has a larger amount of magnesium, which provides greater strength. Nexalloy R-357.0 is typically used in situations where high strength combined with high corrosion resistance and/or pressure tightness are required. Commonly used to weld parts including structural, machine, impellers, housings, pump, valve components, tools, frames, and brackets which are made of alloy 356.0, A356.0, A357.0, 3003, 6005, and 6061.

- TIG

- Available in all standard diameters and packaging

- Nexalloy R-357.0 conform to: AWS A5.10

DIAMETERS AND PACKAGING

NEXALLOY R-A356.0

Nexalloy R-A356.0 is an Aluminum Silicon Copper with high-strength alloy which is used in various applications where castings are usually heat treated for maximum strength. It possesses moderate to high strength (37 ksi typical), low melting temperature and good weldability, formability. R-A356.0 may be used to weld alloy 356.0, A356.0, A357.0, 3003, 6005, or 6061. Common applications include aircraft parts and high strength casting structures in Automotive and Aerospace industries.

- TIG

- Available in all standard diameters and packaging

- Nexalloy R-A356.0 conform to: AWS A5.10

DIAMETERS AND PACKAGING

NEXALLOY R-C355.0 – PRODUCT DATA SHEET

Nexalloy R-C355.0 is an Aluminum Silicon Copper with high-strength alloy which is used in various applications where castings are usually heat treated for maximum strength. It possesses moderate to high strength (36 ksi typical), low melting temperature and good weldability, formability. R-C355.0 may be used to weld alloy 355.0, C355.0, 3003, 6005, or 6061. Common applications in welding light weight, high strength Aluminum castings in Automotive, Aerospace industries.

- TIG

- Available in all standard diameters and packaging

- Nexalloy R-C355.0 conform to: AWS A5.10

DIAMETERS AND PACKAGING

Metalizing Wire

Nexal’s metalizing wire is produced per AWS specifications. It is suitable for flame spray equipment, arc spray coating systems and vacuum proceses.

Standard Alloys & Sizes

All Metalizing wire is custom manufactured for our customers. Normal shipping time is 2 – 3 weeks

Plastic spools

16lb / 7.25kg (1.5mm, 1.6mm, 1.8mm, 2.0mm, 2.4mm, 3.2mm) 26lb / 11.79kg (1.5mm, 1.6mm, 1.8mm, 2.0mm, 2.4mm)

Available in the following alloys:

1075,1080, 1100, 1188 1199, 1350, 4043, 5356

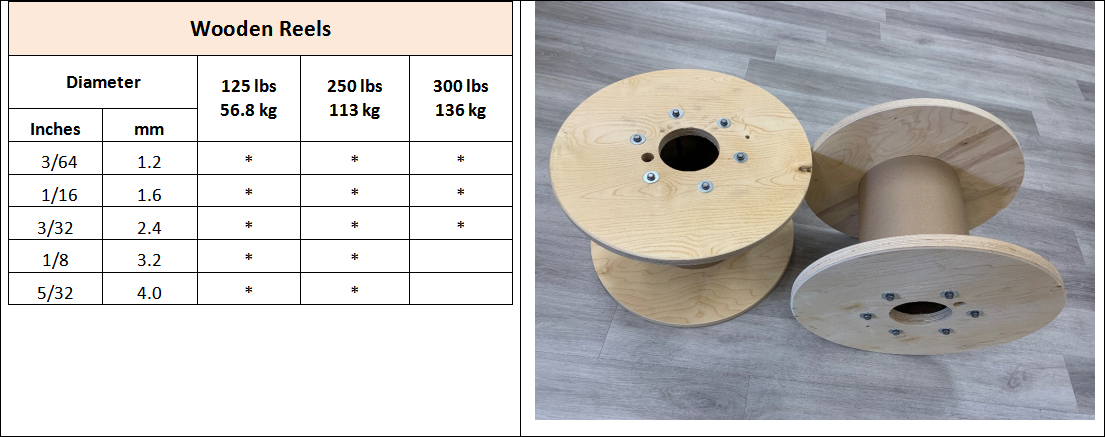

Wooden Reels

125lb / 56.69 (1.5mm, 1.6mm, 1.8mm, 2.0mm, 2.4mm, 3.2mm) 225lb / 102kg (1.5mm, 1.6mm, 1.8mm, 2.0mm, 2.4mm, 3.2mm, 4.0mm, 4.8mm)

Tie Wire

Nexal’s tie wire is used primarily to secure bundles of metal or other materials

Individual Coils

- 50LB – 16Gauge / 1.3mm

- 50LB – 14Gauge / 1.6mm

- 50LB – 11Gauge / 2.3mm

- 50LB – 8Gauge / 3.2mm

- 50LB – 5Gauge / 4.7mm

Available in the following alloys:

1100, 1350, 5356